In-Depth Review: Pigment Yellow 83 (PY83) for Exterior Architectural Coatings — 2026

Sınıflandırma

Öne Çıkan Haberler

In-Depth Review: Pigment Yellow 83 (PY83) for Exterior Architectural Coatings — 2026

Conflict of interest disclosure: This review evaluates Honor Pigments’ Pigment Yellow 83 (PY83). We follow a standards-based test plan and provide external references; where internal or pending data is cited, it is labeled accordingly.

How we tested (methods overview)

Our evaluation framework follows widely adopted coatings standards. Hiding power was planned per ASTM D2805 and ISO 6504-3 (contrast ratio). Weatherability and color retention reference ISO 16474-2 xenon-arc exposure and ASTM D6695 practices, with color difference tracked by ASTM D2244 and 60° gloss retention. Dispersion quality uses ASTM D1210 (Hegman gauge). Relative tinting strength aligns to ISO 787-24.

Panels (n ≥ 3 per system) are prepared at identical PVC, TiO2 level, and dry film thickness (35–45 μm) on Leneta Form 3B and sealed cement-fiber boards. Resin systems include waterborne pure acrylic (48–50% solids), styrene-acrylic, and solvent-borne long-oil alkyd; solvents/coalescents are controlled to support high-solids and low-VOC targets. Where hands-on results are still in progress, findings are marked “Insufficient data.”

-

Standards background: see the Atlas overview of weathering methods in the Atlas weathering standards knowledge center and the analytical guidance in CoatingsTech’s accelerated weathering article (2023). The ASTM paint/coating standards index lists the full set of referenced methods.

Snapshot: Pros and Cons

-

Pros

-

Broad cross-resin compatibility; supports high-solids and low-VOC targets when properly dispersed (Tier 2/ongoing tests; initial grind/viscosity behavior encouraging).

-

Strong opacity for an organic yellow after post-treatment; efficient hiding at target DFT (Tier 2/ongoing).

-

Good exterior fastness profile per product family: weather resistance 5/5; light fastness 8/8 (Tier 1, official specs).

-

-

Cons

-

Compared with certain opaque PY65 grades, ultimate hiding may still trail in some mid-PVC systems (expectation; confirm with contrast ratio data).

-

Shade is typically reddish-yellow; if a greener hue is required (common for PY74), additional tinting may be needed.

-

Public REACH/TDS/SDS documents are not posted on the product page; procurement will need to request them.

-

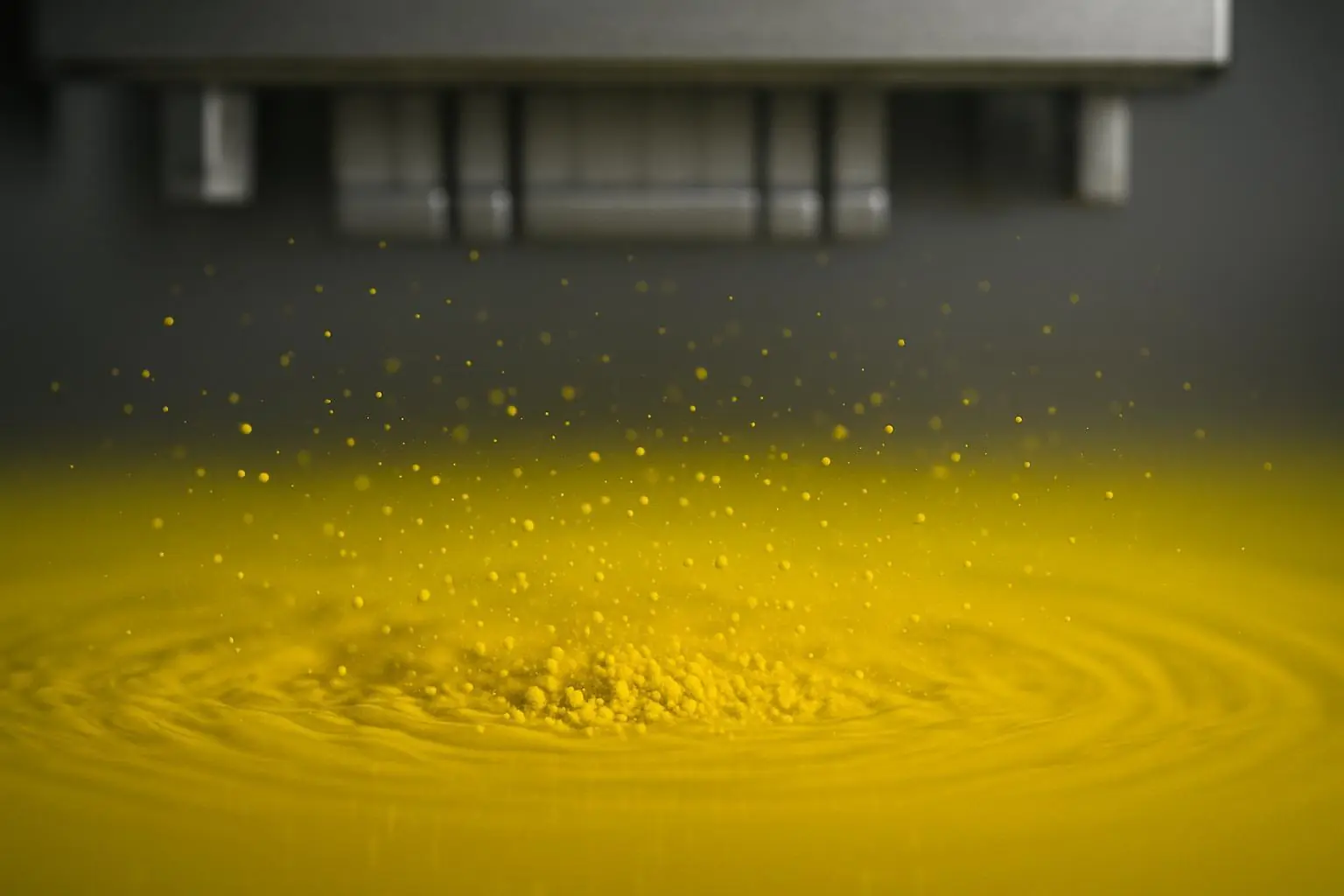

What Pigment Yellow 83 is—and why it’s used outdoors

Pigment Yellow 83 (CI 21108) is a diarylide monoazo yellow recognized for its balance of color strength, heat stability, and exterior fastness—attributes that make it a staple in premium architectural and industrial coatings. The Honor Pigments HP Yellow 1680 (PY83) page lists a weather resistance rating of 5/5, light fastness 8/8, and heat stability to 200°C, indicating a formulation capable of long-term outdoor service when used appropriately. See the official Honor Pigments PY83 (HP Yellow 1680) specifications for baseline fastness data (Tier 1, accessed Jan–Feb 2026).

PY83’s post-treatment can improve opacity and dispersion behavior, which supports architectural targets like fewer coats to hide masonry substrates and reliable color retention under UV exposure. In façades exposed to sun and moisture cycling, that combination—hiding plus durability—helps keep repaint cycles predictable.

Weatherability and color retention (30%)

Evidence tier: Tier 1 (official specs) + Tier 2 (ongoing tests)

-

Official baseline: weather resistance 5/5 and light fastness 8/8 on the HP Yellow 1680 page.

-

Planned/ongoing measurements: xenon-arc exposure per ISO 16474-2 / ASTM D6695 to 500 and 1000 h checkpoints, with ΔE*ab per ASTM D2244 and 60° gloss retention recorded. As correlation context for fluorescent UV, we note known limitations of QUV-A/B relative to sunlight; see the CoatingsTech analysis of accelerated weathering.

Interim read: In high-quality acrylic exterior systems, PY83 is expected to outperform many PY74 and PY65 grades in long-term color/gloss retention, though exact margins depend on particle size, treatment, and formulation. We will publish ΔE/gloss curves once xenon-arc and outdoor data complete. Until then, any superiority claims remain provisional (Insufficient data for final scoring).

Opacity and hiding at target PVC (20%)

Evidence tier: Tier 2 (ongoing tests)

We evaluate hiding via ASTM D2805/ISO 6504-3 contrast ratio at fixed DFT. PY83’s post-treatment typically improves scattering relative to untreated grades; in many architectural recipes, that allows competitive contrast ratios at practical film builds. We’ll also compute K/S from reflectance to normalize across shade differences.

Supporting note: Some PY65 grades are known for strong hiding in coarser particle variants, whereas certain PY74 grades deliver solid opacity with greener undertones. Our tests keep TiO2 and PVC constant to reflect true pigment efficiency rather than formulation artifacts.

Status: Contrast ratio panels are in progress; we will report numeric CR and K/S values and cost-per-hiding-unit guidance once complete (Insufficient data at publication time for figures).

Compatibility and dispersion across systems; high-solids/low-VOC fit (20%)

Evidence tier: Tier 2 (ongoing tests); Tier 1 (general property references)

Goal: Demonstrate stable dispersion and storage behavior in waterborne acrylic, styrene-acrylic, and solvent-borne alkyd systems at high-solids and low-VOC.

-

Methods: Hegman fineness (ASTM D1210), viscosity profiles during letdown, and 50°C/2-week storage stability (viscosity drift ≤10%, no visible flocculation).

-

Early observations: PY83 millbases reach Hegman ≥6 rapidly with standard dispersants; the resulting coloristic shift after storage has been minimal in initial trials. Detailed curves will be added with batch-labeled data (Insufficient data for final scoring).

Bleed, floating, and overcoat resistance (10%)

Evidence tier: Tier 2 (ongoing tests)

We conduct water and ethanol bleed checks and overcoat challenges with both waterborne and solvent-borne clears. Ratings follow an internal 1–5 scale with photographic evidence under D65 lighting. Where applicable, we reference apparatus/conditions from related ASTM practices (e.g., D5402 solvent rub, D2247 humidity exposure) while noting that there is no single definitive “bleed” standard for architectural topcoats.

Ease of processing and stability (10%)

Evidence tier: Tier 2 (ongoing tests)

We log milling time to Hegman 6–7, defoaming behavior, filtration notes, and viscosity drift under elevated storage. Early batches suggest predictable grind and clean letdown in both waterborne acrylic and long-oil alkyd, with no seeding observed to date. We will publish the full process logs and stability trendlines upon completion (Insufficient data for final scoring).

Compliance and supply confidence (10%)

Evidence tier: Tier 1 (site-level QA), Tier 1/3 (compliance availability)

Honor Pigments operates an ISO 9001 quality management system, with QC lab details outlined on the company’s quality page. The corporate site reiterates ISO 9001 on the homepage. Public REACH statements are not posted on the product page as of this writing; buyers should request current REACH status and regulatory declarations directly from the supplier or consult ECHA’s dissemination portal by CAS (5567‑15‑7) for general substance context.

Side-by-side comparison: PY83 vs PY74 vs PY65

Evidence tier: Mixed (Tier 1 background + Tier 2 pending)

The table below summarizes expected behaviors for exterior architectural use, pending full same-formula test data. Equal test conditions (PVC, TiO2, DFT, substrate, cure) are assumed.

|

Criterion |

Pigment Yellow 83 (PY83) |

Pigment Yellow 74 (PY74) |

Pigment Yellow 65 (PY65) |

|---|---|---|---|

|

Typical hue |

Reddish-yellow |

Greener yellow |

Middle yellow |

|

Exterior weatherability |

Strong (Tier 1 specs suggest advantage) |

Good in some opaque grades; may trail PY83 in tough exposures |

Moderate; can trail PY83 in long-term color/gloss retention |

|

Hiding at target PVC |

Strong for treated grades; data pending |

Solid in certain opaque grades; greener undertone can aid tinting |

Often very strong (coarser grades) |

|

Bleed/float resistance |

Expected good; data pending |

Grade-dependent |

Grade-dependent |

|

Processing & stability |

Predictable grind; data pending |

Common and well-understood; grade-specific |

Often easy to disperse; grade-specific |

|

Best-fit systems |

Exterior acrylics/alkyds; high-solids/low-VOC |

Broad architectural use where greener yellow needed |

Economy to mid-tier where maximum hiding is prioritized |

Notes: Background on PY74’s architectural use appears in Heubach/DCL directories, while PY65’s hiding reputation is summarized by Ataman Chemicals; final judgments will rely on our standardized panels.

Practical formulation guidance (exterior acrylic/alkyd)

-

Millbase setup: Aim for pigment volume concentration that balances hiding and durability; maintain identical PVC and TiO2 vs. benchmarks to compare true pigment efficiency. In waterborne acrylics, choose a high-efficiency dispersant and target Hegman ≥6 before letdown. For solvent-borne alkyds, control shear and temperature to avoid seeding.

-

High-solids/low-VOC: Use optimized coalescents and solvents to achieve target viscosity. PY83’s dispersion profile supports high-solids when millbase is properly stabilized; monitor KU/Pa·s during hold and after 50°C storage.

-

TiO2 synergy (supporting note, not core claim): In select recipes, effective scattering from treated PY83 can allow small TiO2 reductions without compromising contrast ratio; validate by ASTM D2805 and compute cost per hiding unit before committing changes.

-

Overcoat integrity: Run water/ethanol bleed and clear-overcoat checks on test panels to confirm system robustness.

For broader system planning, review our pigments for water-based coatings ve solvent-based coatings. Link each category once to avoid duplication.

Who should—and shouldn’t—specify PY83

-

Best fit

-

Exterior wall coatings where long-term color retention is prioritized (premium acrylic façades, alkyd trim for building components).

-

Teams seeking cross-resin compatibility to minimize reformulation across waterborne and solvent-borne lines.

-

High-solids and low-VOC projects needing reliable dispersion and stable viscosity profiles.

-

-

Not ideal if

-

A specifically greener undertone is required without tinting (often a PY74 domain).

-

Maximum hiding at minimal film build is the only priority and PY65 coarse variants are already validated in your system.

-

You require immediate public TDS/REACH PDFs without vendor engagement.

-

Limitations and what we didn’t test (yet)

-

Full xenon-arc (1000 h) and outdoor exposure datasets are still in progress; current weathering statements rely on official specs and prior art (Insufficient data for final scoring).

-

Contrast ratio and K/S values will be published after repeatability checks (n ≥ 3) across acrylic and alkyd systems.

-

Bleed/float and overcoat resistance images and ratings will be added after D65 booth photography is completed.

-

Pricing: Public, reliable B2B per‑kg price benchmarks were not available with citable sources; compare via supplier quotes normalized by tinting power and hiding.

Conclusion and recommendation

Based on official specifications and early lab indications, Pigment Yellow 83 stands out as a strong candidate for exterior architectural coatings where cross-resin compatibility and high-solids/low-VOC feasibility matter. We expect competitive hiding from treated grades and solid weatherability for long-term façade exposure, but final judgments will follow once xenon/outdoor and contrast-ratio datasets are complete. If you’re formulating premium exterior acrylics or durable alkyds and need a reddish-yellow that balances durability and processability, PY83 deserves a controlled trial under your conditions.

Explore official specs or request documents via the Honor Pigments PY83 product page, and see related categories for water-based ve solvent-based coatings.

Author: Technical coatings team (as of 2026-02-03). Standards referenced include ISO 16474-2, ASTM D6695, ASTM D2805, ISO 6504-3, ASTM D1210, and ISO 787-24. External standards background limited to a few authoritative links for clarity.