PR170 HP RED 2130: The Practical Guide to Pigment Red 170 for High‑Grade Coatings, Plastics, and Inks

Sınıflandırma

Öne Çıkan Haberler

PR170 HP RED 2130: The Practical Guide to Pigment Red 170 for High‑Grade Coatings, Plastics, and Inks

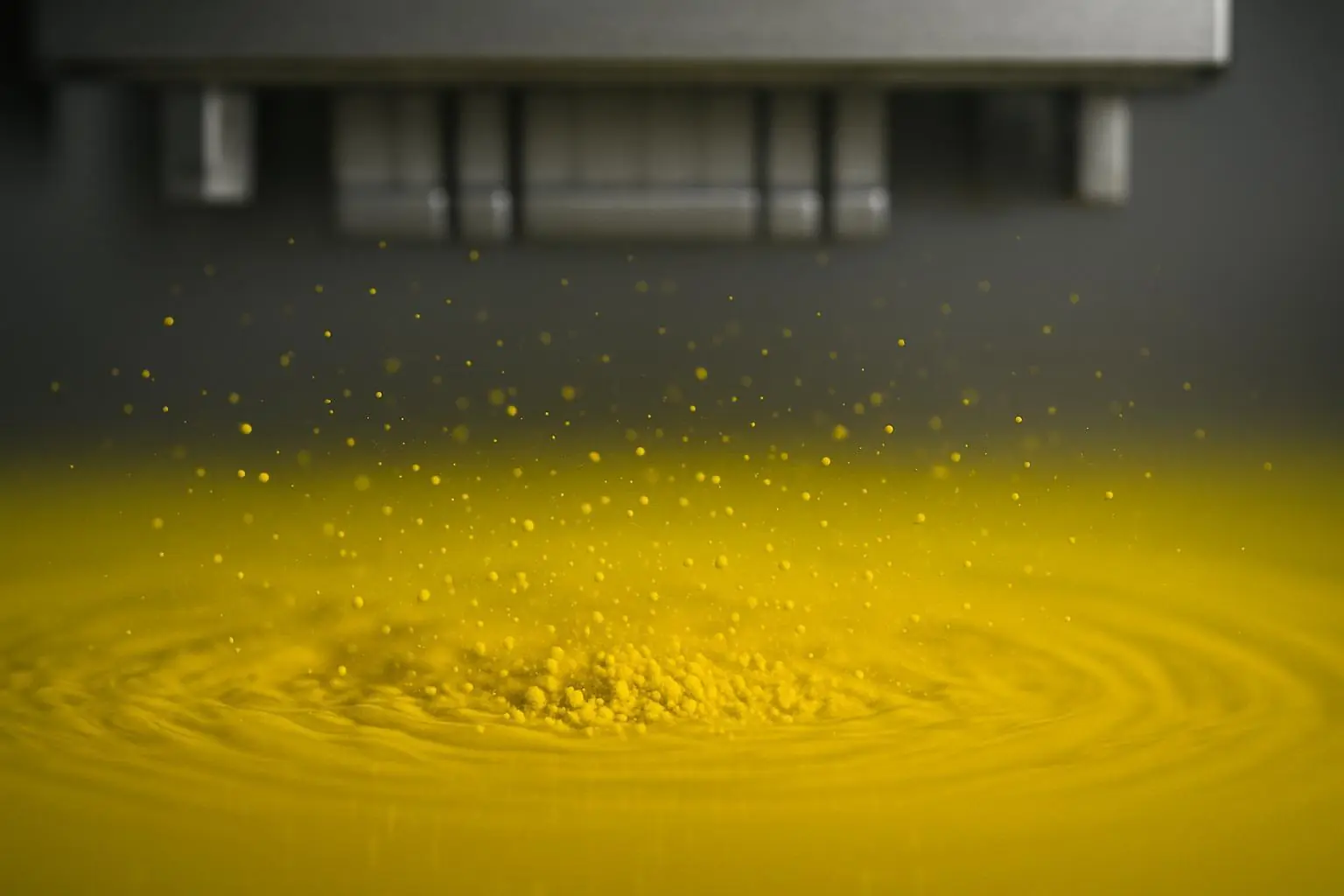

If you formulate exterior coatings, engineer PP/PA/PC compounds, or specify printing inks, you’ve likely short‑listed Pigment Red 170 more than once. This guide lays out how a high‑performance PR170 grade such as PR170 HP RED 2130 can serve as a single differentiator across systems by holding color under UV, heat, solvents, and processing stress—while staying reproducible lot to lot. Every performance claim here is tied to recognizable methods (ISO/ASTM) and realistic acceptance examples, so you can map it to your own internal standards.

—

The Single Differentiator: Durable, Stable Color Across Systems

When we say a single differentiator, we mean one integrated outcome: durable, stable color you can trust from lab to line. In practice, that’s five things working together:

Outdoor weathering and lightfastness that remains credible in both full shade and 1:3 TiO2 tint.

High‑heat color stability across common polymer windows (PA/PC/PP) without unacceptable hue drift after melt/hold.

Low migration tendencies and practical solvent/chemical resistance in coatings and inks.

Batch‑to‑batch chroma and hue consistency that shortens matching cycles and stabilizes QC.

Selectable transparency/opacity options that support the hiding, gloss, and rheology targets of each system while dispersing cleanly.

Think of it this way: you’re not chasing five different reds—you’re choosing one chemistry whose grade design and process controls allow you to meet five interlocking requirements.

Pigment Red 170 Fundamentals: Crystal Forms, Opacity vs Transparency

Pigment Red 170 (C.I. 12475) is a naphthol AS monoazo red known for multiple crystal forms and commercial variants. Opaque, yellow‑shade forms (often used for coatings and PVC) emphasize hiding and robust full‑shade weathering; transparent, bluish‑shade forms (favored in inks and packaging) emphasize clean tints and filtration. Peer‑reviewed work has shown that denser polymorphs (for example, γ‑phase obtained via hydrothermal conversion) can improve thermal stability and flow while narrowing particle size distributions—factors that influence tint strength, rheology, and color hold under heat. See the γ‑phase conversion and property improvements documented in a 2023 open‑access study on PR170 crystalline transformations and kaolin surface modification in the RSC/PMC literature: the authors quantified phase conversion conditions and linked microstructure to processing behavior (peer‑reviewed γ‑phase insights).

Two practical implications for formulators:

For exterior coatings where hiding and long‑term durability matter, an opaque PR170 form with controlled particle architecture often gives stronger full‑shade weathering and solvent fastness.

For high‑purity inks or fine tints where filtration and transparency matter, a transparent PR170 form supports cleaner undertone and easier dispersion, with the understanding that tint lightfastness is usually the limiting factor and must be validated.

How We Prove It: Standardized Tests and Acceptance Examples

To keep discussions concrete, the table below maps common claims to widely used test methods and example parameters. Always align acceptance limits with your OEM or internal SOPs.

Claim focus | Primary method(s) | Typical parameters to document | Example acceptance (illustrative) |

|---|---|---|---|

Lightfastness (full & 1:3 TiO2 tint) | ISO 105‑B02; ASTM D4303 | Xenon‑arc exposure; record ΔE*ab and Blue Wool rating; note full vs tint | Full shade ≥6–7 on 1–8 scale; tint ΔE ≤1.5 at defined exposure; document method variant (method overview) |

Exterior weathering of coatings | ISO 4892‑2 / ASTM G155 (xenon‑arc); ASTM G154 (QUV) | Film type, resin, UV irradiance, cycle time; gloss at 60°; adhesion | After 500 h QUV (UVA‑340): gloss retention ≥85%; xenon 1,000 h: tint ΔE ≤1.5 (program‑dependent) (Atlas automotive weathering) |

Heat stability in plastics (PP/PA/PC) | Internal thermal hold aligned to polymer window; reference ASTM D3451 sections | 240/260/280 °C × 10 min holds on pellets/plaques; track ΔE and hue angle | ΔE ≤1.0–1.5 and minimal hue shift at target processing temp; escalate if drift seen (γ‑phase rationale) |

Solvent/chemical resistance | Vendor scale 1–5 with named media | MEK double rubs, xylene, ethanol; 5% HCl/5% NaOH; time/concentration | 4–5 ratings in xylene/ethanol; 3–4 in MEK; acids/alkalis 5 where resin allows (representative TDS scale) |

Migration/set‑off (inks, screening) | EN 1186 (overall/specific migration); EuPIA guidance | Food simulant, time/temp, surface area; GC‑MS/LC‑MS analytics | Meet OML/SML per substrate/regulation; escalate to accredited lab for compliance (EuPIA test guidance) |

Performance Expectations for Pigment Red 170 (What’s Typical and How to Read It)

Publicly available summaries for Pigment Red 170 commonly report full‑shade lightfastness in the 6–7 range on the 1–8 scale, with tint performance lower and more grade‑dependent. These ranges reflect xenon‑arc/Blue Wool‑type exposures rather than casual window tests; verify the exact protocol before comparing numbers across suppliers. A method summary for lightfastness and the meaning of ASTM/ISO variants is provided in Micom’s overview of colorfastness testing (ASTM/ISO lightfastness context). For accelerated exterior durability of coatings, xenon‑arc per ISO 4892‑2 or ASTM G155 and fluorescent UV/condensation per ASTM G154 (QUV) are standard; Atlas’ automotive weathering guidance explains how to set realistic irradiance and cycling (designing automotive weathering programs).

Heat stability claims for PR170 in plastics are often quoted around 240–260 °C, with some high‑performance implementations holding color up to ~280 °C under short‑duration conditions. Numbers vary because test set‑ups vary (hold time, substrate, antioxidant package). When evaluating for PA/PC/PP, insist on ΔE*ab and hue‑angle reporting at clearly stated temperatures and times, not just a single “max °C.” Peer‑reviewed crystallography work on PR170’s denser polymorphs (e.g., γ‑phase) supports improved thermal behavior under melt (γ‑phase conversion improves processing behavior).

On solvent/chemical resistance, expect 1–5 scales with MEK/xylene/ethanol/acid/alkali specifically named and exposure times listed. Representative TDS tables for a PR170 show ratings like MEK 3–4, xylene 4–5, ethanol 4–5, acids/alkalis 5; always interpret these in the context of your resin and cure (example resistance table reference). For packaging‑adjacent inks, use EN 1186 overall migration with EuPIA’s testing roadmap to screen before engaging accredited compliance programs (EuPIA migration testing framework).

Exterior Coatings Hero: Automotive & Industrial Tint Stability That Holds Up

Exterior topcoats live or die by tint stability. A practical workflow to qualify PR170 HP RED 2130 in an acrylic or polyester‑melamine system looks like this: disperse to a defined Hegman fineness, draw down full shade and 1:3 TiO2 tint, and cure per resin TDS. Run parallel weathering: (1) QUV UVA‑340 per ASTM G154 with 8 h UV/4 h condensation cycles to 500 h; (2) xenon‑arc per ISO 4892‑2 or ASTM G155 to 1,000 h on a right‑light filter set. Track gloss at 60° and ΔE*ab, and specify a tint ΔE target such as ≤1.5 at 1,000 h (your OEM may set 1.0–1.2). Adhesion (ASTM D3359, aim for 5B) and MEK rub resistance are logged as secondary checks. Atlas’ automotive weathering notes provide parameter selection guidance to ensure tests are meaningful rather than punitive (automotive weathering parameter selection).

Where Pigment Red 170 earns its place is the combination of robust full‑shade durability and manageable tint performance, especially in the opaque forms designed for coatings. If your tint is the limiter, adjust pigment volume concentration (PVC), dispersant package, and TiO2 type/level—then re‑run xenon and QUV. Many labs also monitor hue‑angle drift because small Δh, even at low ΔE, can be visually unacceptable for automotive matches.

For deeper due diligence without violating vendor naming policies, you can set up an anonymized side‑by‑side: PR170 HP RED 2130 versus a generic “standard PR170‑type reference” at equal loading and grind, then compare ΔE and gloss retention under identical programs. Keep the report numerical and method‑anchored.

For additional reading on pigments selected for coatings applications, see the coatings category overview on Honor Pigments’ site, which outlines application contexts and quality system credentials (pigments for coatings and paints).

Powder & Coil Coatings Hero: Weathering and Mechanical Balance

Powder and coil coatings impose two filters before outdoor exposure even begins: cure temperature/time and post‑cure mechanicals. Typical polyester powder windows are 180–200 °C for 10–20 min; coil lines often use stoving cycles of similar magnitude. Start with a bake‑screen panel set at your line’s low, nominal, and high cure profiles. Record color drift and gloss, then run solvent resistance (MEK double rubs) and adhesion (ASTM D3359). Next, take the nominal cure set into QUV and xenon‑arc programs. A balanced outcome looks like: minimal ΔE on bake‑sensitivity, passing solvent rubs, 5B adhesion, ≥85% gloss retention at 500 h QUV, and controlled tint ΔE under xenon.

The choice between more opaque vs more transparent PR170 forms affects hiding versus clean undertone in powders; for exterior durability, denser/opaque forms are usually favored. If your finish targets a metallic or thin‑film coil build where transparency helps with flop and sparkle, run an extended xenon program because tint lightfastness will be your governor.

If you need a quick sense of fit for this application family, Honor Pigments maintains application category pages, including powder and coil sub‑pages, that outline typical resin/pigment pairings and processing contexts (pigments for powder coatings ve pigments for coil coatings).

Engineering Plastics Notes: Heat‑Hold and Color Drift in PA/PC/PP

In polymers, you’re validating whether Pigment Red 170 can tolerate your melt history. A practical lab screen for PR170 HP RED 2130 uses stepwise thermal holds on compounded plaques or pigmented pellets: 240/260/280 °C × 10 min (match to PP/PA/PC ranges), then measure ΔE*ab and hue angle against an unexposed control. Flag any hue rotation that would fail a visual panel. If drift is observed at the top temperature, try a lower‑temperature, longer hold matching your real residence time; pigment‑resin‑stabilizer interactions matter.

The microstructure story from crystallography—denser polymorphs such as γ‑phase showing improved thermal behavior—lines up with what processors see: certain PR170 implementations give better color hold when the crystal form and particle distribution are tuned. For a quick context on how crystalline modifications influence processing properties, see the open‑access γ‑phase conversion study linking hydrothermal treatment to improved flowability and stability (γ‑phase conversion study).

If your business also runs masterbatch or concentrates, the dispersion pathway (two‑stage vs direct‑let‑down), screw design, and stabilizer package can affect the perceived heat stability as much as the pigment itself. Validate on your exact line.

For reference on application families and available pigment classes in plastics, see the plastics & masterbatch category page on Honor Pigments’ site (pigments for plastics and masterbatch).

Solvent Resistance and Low‑Migration Context for Inks

In ink systems, PR170’s solvent and chemical resistance are typically summarized on a 1–5 scale per named medium (MEK, xylene, ethanol, weak acid/base). Read these ratings alongside your vehicle, cure, and substrate—flexo nitrocellulose behaves differently than UV acrylate. For packaging‑adjacent scenarios, treat low migration as a system property, not a pigment property alone. Screen with EN 1186 overall/specific migration protocols and follow the industry roadmap from the European printing inks association for test selection, simulants, and escalation (EuPIA migration testing guidance). If early screening is promising, commission accredited lab work per your customer’s regulatory framework.

A Practical Micro‑Example (Disclosure Included)

Disclosure: Honor Pigments is our product.

Two quick lab workflows show how PR170 HP RED 2130 can be screened for the hero scenarios without over‑promising:

Automotive/industrial topcoat tint: Mill to target fineness; prepare full shade and 1:3 TiO2 tint panels in an acrylic‑melamine. Run QUV UVA‑340 to 500 h (gloss target ≥85%) and xenon‑arc (ISO 4892‑2) to 1,000 h with tint ΔE ≤1.5 as the provisional pass. If the tint struggles, adjust PVC/dispersion and re‑test rather than increasing pigment load indiscriminately.

PP compounding heat‑hold: Compound a 1% masterbatch, let down to 0.2–0.3% in PP; press plaques, then hold at 240/260/280 °C × 10 min. Accept if ΔE ≤1.5 and hue rotation is negligible at your line’s true temperature. If marginal at 280 °C, verify whether actual residence time/temperature justifies that hold or if stabilizers need adjustment.

For background on the company’s quality system and application focus (ISO 9001; coatings, plastics, inks), see the Honor Pigments home page (Honor Pigments, ISO 9001 profile).

Troubleshooting Quick Answers

My tint fails xenon‑arc before the masstone: This is common with organic reds. Re‑balance TiO2 type/level, lower PVC, and verify dispersant selection; re‑run xenon before changing pigment chemistry.

I see a small but visible hue shift in PP at 260 °C: Confirm residence time. If line reality is closer to 240–250 °C, reset the hold profile; if not, evaluate stabilizer synergy or a denser‑polymorph implementation of PR170.

Solvent rubs fail after QUV: Check under‑cure or over‑exposure. Validate your cure window first; pigment fastness readings are unreliable if the film isn’t fully developed.

Next Steps

If you need a data sheet, a method sheet aligned to your lab, or a small batch for trials, request a technical packet; we’ll align test parameters to your resin and processing window and share anonymized, method‑anchored benchmarks on request.