ПИГМЕНТНЫЙ ЖЕЛТЫЙ 14/ HP ЖЕЛТЫЙ 1543

ПИГМЕНТНЫЙ ЖЕЛТЫЙ 14/ HP ЖЕЛТЫЙ 1543

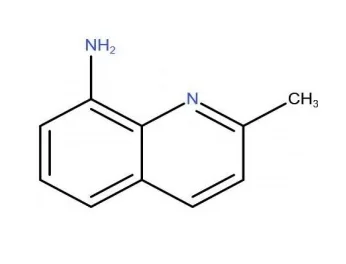

C.I.NO: PY14

Advantage: Transparency, Low viscosity

Основные области применения: Краски на основе растворителей, офсетные краски

Описание

Описание товара - PY14

HP YELLOW 1543 (PIGMENT YELLOW 14) is a vibrant, medium-shade diarylide yellow pigment renowned for its bright red-yellow hue, high opacity, and excellent fastness properties, including lightfastness rated at 3-4, heat resistance up to 180-200°C, and superior solvent resistance that prevents blooming or migration. In solvent-based inks, PY14 excels due to its strong transparency options, good gloss, low viscosity, and stability against overpainting and paraffin wax, making it ideal for packaging, publication gravure, and flexographic printing applications where durable, high-color-strength yellow tones are essential for vibrant, long-lasting results. Additionally, its resistance to paraffin further makes it a useful product for packaging inks.

Рекомендуемое применение:

Coatings: industrial paints, solvent based coatings

Краски для печати: офсетные краски, краски на основе растворителя

Технические данные:

| Информация о продукте | ||||

| Химический тип | Диарилид | CAS NO. | 5468-75-7 | |

| C. I. Name | Пигмент желтый 14 | EINECS / ELINCS NO. | 226-789-3 | |

| C. I. Конституция №. | 21095 | Химическая формула | C34H30Cl2N6O4 | |

| Технические характеристики | ||||

| Полная тень | Тонировка | |||

| Устойчивость к погодным условиям | 4-5 | 4 | Термостабильность °C | 220°C |

| Светостойкость | 7 | 6~7 | ||

| Физические свойства | ||||

| Физическая форма | Порошок | Устойчивость к кислоте | 5 | |

| Удельная плотность (г/см3): | 1.60 ± 0.1 | Устойчивость к щелочам | 5 | |

| Удельная поверхность (㎡/г): | 40 | |||

| Поглощение масла | 50 | |||

| Значение pH | 6.0 - 8.0 | |||

| Летучие вещества | 1% макс. | |||

| Упаковка | ||||

| 25 кг/мешок 350 кг/поддон | ||||

| Хранение | Срок годности | 5 лет | ||

| Хранить в прохладном, сухом и проветриваемом месте. | ||||

| ТРАНСПОРТ | ||||

| Избегайте инверсии, солнечного света, влаги и падения. Избегайте повреждения упаковки. | ||||

- Светостойкость: Светостойкость оценивается по шкале Blue Wool от 1 до 8, где 1 = ‘плохо’, а 8 = ‘отлично’.

- Термостабильность: Приведенные значения термостабильности указывают на максимальную температуру, при которой пигмент можно выдерживать в течение 10 мин. на полном оттенке и в убавлениях без существенного изменения оттенка.

- Поглощение масла: Поглощение масла определяется на основе EN ISO 787-5 и указывается в г льняного масла на 100 г пигмента.

- Кровотечение в растворителях: Кровоточивость в растворителях проверяется с помощью порошковых сортов и визуальной оценки по шкале Грея от 1 до 5.

где 1 = ‘Сильное кровотечение’ и 5 = ‘Без кровотечения”

Отказ от ответственности - Информация, представленная в данном техническом паспорте, основана на текущем состоянии наших знаний и предназначена для общего описания наших продуктов и их возможного применения. В связи с многообразием рецептур, условий производства и применения, все вышеуказанные данные должны быть скорректированы в соответствии с условиями конкретного производителя. В отдельных случаях из этого факта не может быть выведена никакая ответственность, в том числе в отношении патентных прав. Не исключено, что данный продукт содержит частицы < 0,1 мкм. Любой пользователь данного продукта несет ответственность за определение пригодности продукции Sudarshan для конкретного применения и за соблюдение любых прав собственности и существующих законов и законодательства.