PIGMENT RED 48:2/ HP RED 2598

PIGMENT RED 48:2/ HP RED 2598

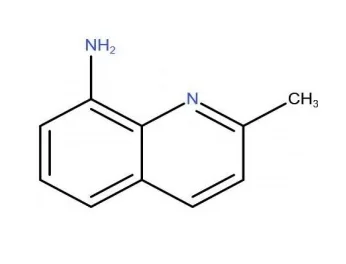

C.I.NO.: PR48:2

Vantagens: Bom brilho, baixa viscosidade

Aplicação principal recomendada: Tintas à base de solventes

Descrição

Descrição do produto - PR48:2

HP Red 2598 (Pigment Red 48:2) is a calcium lake pigment. Widely used in gravure printing inks, especially NC-based packaging inks, it enhances viscosity in water-based inks for smooth, consistent results. With high color strength, excellent dispersibility, and good solvent resistance (MEK rating 3-4), it is insoluble in water, non-flammable, and non-explosive. Ideal for offset, flexographic, and solvent-based inks, it delivers vivid colors for packaging, publications, and textiles.

Aplicação recomendada:

Coatings: solvent based paints, water based paints, industrial coatings

Tintas de impressão: tintas offset, tintas à base de solventes

Dados técnicos:

| Informações sobre o produto | ||||

| Tipo de produto químico | Azo | CAS NO. | 7023-61-2 | |

| C. I. Nome | Pigmento Vermelho 48:2 | EINECS / ELINCS N.º. | 230-303-5 | |

| C. I. Constituição nº. | 15865:2 | Fórmula química | C18H11ClN2O6SCa | |

| Desempenho técnico | ||||

| Sombra total | Tonalidade | |||

| Resistência às intempéries | 4-5 | 3 | Estabilidade térmica °C | 220°C |

| Solidez à luz | 7 | 6 | ||

| Propriedades físicas | ||||

| Forma física | Pó | Resistência ao ácido | 5 | |

| Densidade específica (g/cm3): | 1.70 ± 0.1 | Resistência aos álcalis | 3~4 | |

| Superfície específica (㎡/g): | 58 | |||

| Absorção de óleo | 65 | |||

| Valor do pH | 6.5 -8.5 | |||

| Matéria volátil | 1% máximo | |||

| Embalagem | ||||

| 25kgs/saco 400kgs/Palete | ||||

| Armazenamento | Prazo de validade | 5 anos | ||

| Deve ser armazenado em local fresco, seco e ventilado. | ||||

| TRANSPORTE | ||||

| Evitar a inversão, a luz solar, a humidade e o choque. Evitar danificar a embalagem. | ||||

- Solidez à luz: O grau de resistência à luz é avaliado numa escala de 1 a 8 de lã azul, em que 1 = ‘medíocre’ e 8 = ‘excelente’.

- Estabilidade ao calor: Os valores de estabilidade ao calor indicados indicam a temperatura máxima a que o pigmento pode ser armazenado durante 10 minutos na sombra total e em reduções sem sofrer qualquer alteração significativa da cor.

- Absorção de óleo: A absorção de óleo é determinada com base na norma EN ISO 787-5 e indicada em g de óleo de linhaça por 100 g de pigmento.

- Sangramento em solventes: O sangramento em solventes é testado utilizando os graus de pó e a classificação visual é dada numa escala de 1 a 5 cinzentos

em que 1 = ‘Hemorragia intensa’ e 5 = ‘Sem hemorragia”

Isenção de responsabilidade - As informações fornecidas nesta folha de dados baseiam-se no estado atual dos nossos conhecimentos e destinam-se a uma descrição geral dos nossos produtos e das suas possíveis aplicações. Devido à multiplicidade de formulações, condições de produção e aplicação, todos os dados acima mencionados têm de ser ajustados às circunstâncias do processador. Deste facto não podem ser retiradas quaisquer responsabilidades, incluindo as relativas a direitos de patente, para casos individuais. Não se pode excluir que este produto contenha partículas < 0,1 μm. Qualquer utilizador deste produto é responsável por determinar a adequação dos produtos Sudarshan à sua aplicação específica e por garantir o cumprimento de quaisquer direitos de propriedade e das leis e legislação existentes.