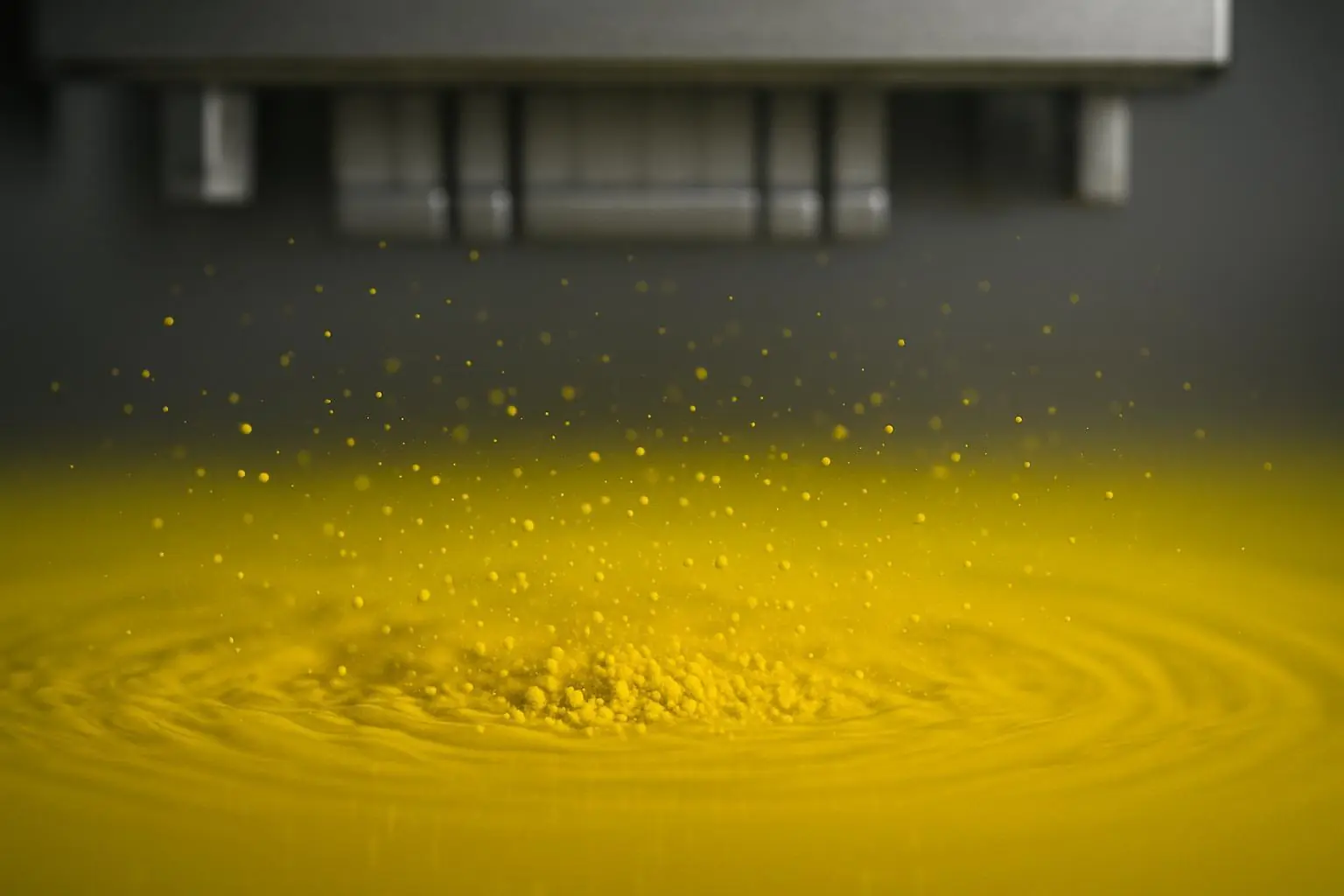

Pigment Red 122 for Inkjet Inks and Laser Toners — A Formulator-Level Deep Dive

Pigment Red 122 for Inkjet Inks and Laser Toners — A Formulator-Level Deep Dive

Pigment Red 122 is the go-to quinacridone magenta when you need high chroma, strong lightfastness, and dependable heat and chemical resistance in digital printing. This tutorial walks through a practical, formulator-level workflow to select a PR122 grade, build a stable aqueous inkjet concentrate and finished ink, adapt to solvent and UV systems, and translate the same pigment to electrophotographic toner. You’ll get numeric targets, verification checkpoints, and a compact reference table to keep development on track.

Why Pigment Red 122 works for digital printing

Pigment Red 122 (C.I. 73915; CAS 980-26-7) offers a clean bluish-red hue, high tinting strength, and durability that survives milling, jetting, and toner processing. Multiple supplier documents report Blue Wool lightfastness typically at 7–8 with heat stability around 280–300 °C and strong solvent and chemical resistance (often rated 4–5 on 1–5 scales). See the property summary in Ranbar’s product page, which highlights lightfastness and heat stability for PR122, and aligns with other supplier summaries and TDS documents listed later in this post for corroboration: the Ranbar PR122 overview.

Materials and equipment checklist

-

Pigment: fine-particle Pigment Red 122 grade for digital inks

-

Dispersant(s): polymeric dispersant suitable for organic pigments (quinacridones)

-

Media milling: lab bead mill with 0.1–0.5 mm YTZ or equivalent beads; high-shear premixer

-

Measurement: DLS for nano PSD, SPOS or laser diffraction for oversize counts; viscometer; tensiometer

-

Filtration: staged depth filters (e.g., 10 → 5 → 1–2 µm) and compatible housings; inline 5–10 µm elements for press

-

QC: zeta potential, pH meter, colorimetry (CIELAB), accelerated aging oven, decap/open-time fixture

Step-by-step: aqueous inkjet PR122 concentrate and final ink

The main use case is water-based inkjet. The goal is a narrow, sub-150 nm dispersion that resists agglomeration, filters reliably, and meets printhead viscosity and surface-tension windows.

-

Select the grade and set targets

-

Choose a fine-particle PR122 with inkjet intent. Inkjet-focused PR122 offerings emphasize narrow PSD and high purity; for example, Sudarshan’s inkjet magenta page underscores ultra-fine particle control for stable jetting: Sudarshan Ink Jet Magenta E 02.

-

Practical PSD window at release: D50 ≤ 100–150 nm; D90 ≤ 200–250 nm; minimal population >0.5 µm.

-

Build a stable concentrate

-

Premix PR122 with a polymeric dispersant and aqueous vehicle. Start with 0.1–2.0 parts dispersant per 1 part pigment by weight and optimize by viscosity minimum and adsorption plateaus. Steric or electrosteric stabilization is the mechanism; polymer anchoring principles are outlined in AFCONA’s dispersing technology primer.

-

Media mill with small ceramic beads, control temperature (<40 °C) to protect viscosity and prevent foaming. Sample periodically; stop when D50 is within target and oversize counts are acceptable.

-

Verify the dispersion

-

Measure PSD by DLS for the main mode and use SPOS/laser diffraction for tail detection. A complementary method is critical to catch rare oversize particles that threaten nozzles; Entegris explains this oversize sensitivity in its SPOS application note: Entegris AccuSizer particle sizing of inkjet inks.

-

Check zeta potential trends and viscosity versus shear rate. Keep pH in a neutral-to-alkaline window (7–9) suitable for your dispersant chemistry.

-

Let down to a printable ink

-

Typical aqueous pigment concentrates hold 10–20 wt% pigment; final inks often carry 2–6 wt% PR122 depending on density and target optical density.

-

Vehicle: water plus humectants/solvents (e.g., glycerol, diols) and a low-foaming surfactant package tuned for dynamic surface tension around 28–40 mN/m. Viscosity targets depend on your head, but many Dimatix-compatible systems are engineered in the single-digit mPa·s range; Global Inkjet Systems’ overview pages for Dimatix drive electronics provide context on head families and operating windows: GIS on Fujifilm Dimatix products.

-

Filtration strategy for manufacturing and press

-

Use staged depth filtration rather than jumping straight to sub-micron membranes. A practical train is 20 → 10 → 5 µm prefilters, followed by depth elements at 5–1–2 µm depending on stability and flow. Critical Process Filters’ guide outlines why staged depth filtration protects membranes and maintains throughput in pigmented systems: Critical Process particle removal in inkjet formulation.

-

Validate removal of oversize with SPOS counts before production release. On press, 5–6 µm inline elements are common for pigmented fills, with ~10 µm typical for recirculation networks.

-

Stability and printability checks

-

Accelerated aging at 50 °C for 1–2 weeks; observe viscosity drift, sedimentation index, and color shift.

-

Jetting tests: decap/open-time, drop velocity and volume, satellite formation, and nozzle health after extended runs.

-

Colorimetry: set CIELAB targets under your standard light/source setup (e.g., ISO 12647/ISO 3664 viewing) and define ΔE acceptance for production.

Targets and checks summary

|

Aspect |

Practical target or range |

How to verify |

|---|---|---|

|

PSD for inkjet |

D50 ≤ 100–150 nm; D90 ≤ 200–250 nm; negligible >0.5 µm |

DLS for mode; SPOS/laser diffraction for tails; retain samples |

|

Viscosity (aqueous) |

Typically 1–9 mPa·s at 20–25 °C, head dependent |

Brookfield or capillary/rheometer; confirm on printer |

|

Dynamic surface tension |

28–40 mN/m working window |

Maximum-bubble or pendant-drop tensiometer |

|

pH |

7–9, dispersant dependent |

Calibrated pH meter |

|

Filtration train |

20 → 10 → 5 µm prefilters; depth 5–1–2 µm; 5–6 µm inline |

Differential pressure logs; SPOS oversize counts |

|

Aging |

Stable viscosity/color after 1–2 weeks at 50 °C |

Retain sample comparisons; ΔE vs baseline |

Solvent-based and UV-curable variants

Solvent-based inkjet

-

Leverage PR122’s general solvent resistance ratings (often 4–5) by pairing with a compatible resin to prevent re-agglomeration during evaporation. Balance evaporation rate to avoid excessive head cooling. Stage filtration as above, ensuring filter media are solvent compatible.

UV-curable inkjet

-

Choose oligomer/monomer blends that wet the PR122 surface treatment and keep viscosity in the target range for your head family (often 8–20 mPa·s at 25 °C). Confirm substrate surface energy is adequate for adhesion—many ink makers advise treated plastic surfaces above the mid-40s mN/m. For design context and example ink surface tension values, see Nazdar’s technical note for a UV-LED series reporting 32–36 dynes/cm: Nazdar 270 Series UV-LED ink TDS.

Electrophotographic toner processing with PR122

For toner, Pigment Red 122’s thermal robustness supports standard compounding and fusing envelopes. Melt-knead PR122 into a styrene–acrylic or polyester resin with waxes and charge-control agents as needed, then micronize and classify. A practical PSD window is a volume median around 5–11 µm with a narrow tail; HORIBA’s application note shows the major toner population below ~15 µm, which aligns with many production targets: HORIBA toner particle size distribution application note. Validate tribo charge distribution, transfer efficiency, and low offset at the intended fusing temperature profile.

Troubleshooting common issues

Re-agglomeration after milling

-

Likely cause: insufficient adsorbed dispersant or unfavorable ionic strength/pH. Fix by running an adsorption isotherm to confirm dosage, adjusting pH into the dispersant’s effective window, or performing a short re-mill with incremental dispersant addition.

Poor filtration throughput or rapid blinding

-

Likely cause: trying to push pigments through sub-micron membranes without depth prefiltration, or gels from incompatible additives. Fix by adding staged depth elements (10 → 5 → 1–2 µm), optimizing flow and differential pressure, and screening additive compatibility.

Nozzle outs and satellites in press tests

-

Likely cause: oversized tail or dynamic surface tension too high. Fix by tightening the mill endpoint and validating with SPOS oversized counts, then tuning surfactant package to lower dynamic surface tension within range.

Color shift after aging

-

Likely cause: microflocculation or oxidative changes. Fix by adjusting humectant balance, adding antioxidants as appropriate, and verifying zeta potential and PSD after stress.

Weak toner transfer or offset

-

Likely cause: toner PSD too coarse or resin softening mismatch. Fix by reclassifying to narrow D90, blending resins to tune softening point and melt rheology, and reassessing fusing profile.

Practical example with a neutral supplier mention

Disclosure: Honor Pigments is our product.

When sourcing a PR122 grade for water-based inkjet, start by requesting an inkjet-intent PR122 with a guaranteed narrow PSD spec and stable surface treatment. Ask for a D50 ≤ 130 nm and D90 ≤ 200 nm on the supplied dispersion or a milling curve showing these endpoints on your vehicle and dispersant. Confirm filtration behavior across a 10 → 5 → 1 µm train and provide a retain for SPOS counting. For a catalog starting point, the printing inks category at 명예 안료 lists digital-ink-suitable organics, including PR122 variants; use it to initiate a TDS/COA request and sampling protocol.

Validation and release checklist

-

PSD and oversize counts meet targets on retains and after 50 °C aging

-

Viscosity and dynamic surface tension within your printhead’s window

-

Filtration passes staged depth train at production scale without excessive ΔP

-

Stable jetting in decap/open-time tests and clean nozzles after extended runs

-

Colorimetric targets achieved with acceptable ΔE tolerance

-

For toner: PSD window confirmed, tribo and transfer validated, offset minimized at target fusing

References and further reading in context

For property baselines on Pigment Red 122 (lightfastness 7–8, heat stability near 280–300 °C, and solvent resistance), see the supplier summary in the Ranbar PR122 overview. For inkjet-grade particle engineering and fine PSD emphasis, review Sudarshan’s Ink Jet Magenta E 02 page. On filtration design for pigmented inkjet manufacturing, Critical Process Filters’ particle removal guide pairs well with Entegris’ SPOS application note for inkjet inks to verify oversize removal. For printhead operating context, see Global Inkjet Systems’ Dimatix product page. For toner PSD targets and verification, consult the HORIBA application note on toner particle size.