JAUNE PIGMENTAIRE 154/ JAUNE HP 1619

JAUNE PIGMENTAIRE 154/ JAUNE HP 1619

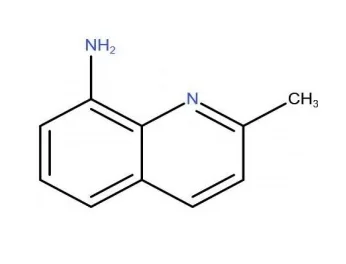

C.I.NO. : PY154

Avantage :

Application principale recommandée : Revêtements

Description

Description du produit - PY154

HP YELLOW 1619 (PIGMENT YELLOW 154) donne une teinte jaune légèrement verdâtre très résistante à la lumière et aux intempéries. Il est totalement ou presque totalement résistant aux principaux solvants organiques. La liste comprend les alcools, les esters, tels que l'acétate de butyle, les hydrocarbures aliphatiques et aromatiques, tels que l'essence minérale ou le xylène, et le phtalate de dibutyle. Il est principalement utilisé dans l'industrie des peintures et parfois dans l'industrie des plastiques et des encres.

Application recommandée:

Revêtements : peintures à base de solvant, peintures à base d'eau, revêtements industriels, revêtements en poudre, revêtements de bobines, peintures automobiles, revêtements pour le bois.

Plastiques : PP, PE, PVC, PS/SAN, ABS, PET, PBT, caoutchouc/TPV, SBC, TPO, TPU

Encres d'imprimerie : encres offset, encres à base de solvant, encres à base d'eau

Données techniques :

| Informations sur le produit | ||||

| Type de produit chimique | Benzimidazolone | CAS NO. | 68134-22-5 | |

| C. I. Nom | Jaune pigmentaire 154 | EINECS / ELINCS NO. | 268-734-6 | |

| C. I. Constitution n°. | 11781 | Formule chimique | C18H14F3N5O3 | |

| Performance technique | ||||

| Pleine ombre | Teinte | |||

| Résistance aux intempéries | 5 | 5 | Stabilité à la chaleur °C | 250°C |

| Solidité à la lumière | 8 | 8 | ||

| Propriétés physiques | ||||

| Forme physique | Poudre | Résistance à l'acide | 5 | |

| Densité spécifique (g/cm3) : | 1.55 ± 0.1 | Résistance aux alcalis | 5 | |

| Surface spécifique (㎡/g) : | 25 | Applications à faible déformation | Adapté | |

| Absorption de l'huile | 54 | |||

| Valeur du pH | 6.5 ~8.5 | |||

| Matières volatiles | 1% max | |||

| Emballage | ||||

| 20 ou 25kgs/sac 400kgs/palette | ||||

| Stockage | Durée de conservation | 5 ans | ||

| A conserver dans un endroit frais, sec et ventilé. | ||||

| TRANSPORTS | ||||

| Éviter l'inversion, la lumière du soleil, l'humidité et les chocs. Éviter d'endommager l'emballage. | ||||

- Solidité à la lumière : La solidité à la lumière est évaluée sur une échelle de 1 à 8 pour la laine bleue, où 1 = ‘médiocre’ et 8 = ‘excellent’.

- Stabilité à la chaleur : Les valeurs de stabilité à la chaleur indiquées correspondent à la température maximale à laquelle le pigment peut être stocké pendant 10 minutes sur la totalité de la teinte et dans les réductions sans subir de changement significatif de teinte.

- Absorption d'huile : L'absorption d'huile est déterminée sur la base de la norme EN ISO 787-5 et indiquée en g d'huile de lin pour 100 g de pigment.

- Saignement dans les solvants : Le ressuage dans les solvants est testé en utilisant les qualités de poudre et l'évaluation visuelle est donnée sur une échelle grise de 1 à 5.

où 1 = ‘Saignement abondant’ et 5 = ‘Pas de saignement”.”

Clause de non-responsabilité - Les informations données dans cette fiche technique sont basées sur l'état actuel de nos connaissances et sont destinées à fournir une description générale de nos produits et de leurs applications possibles. En raison de la multitude de formulations, de conditions de production et d'application, toutes les données susmentionnées doivent être adaptées aux circonstances du transformateur. Aucune responsabilité, y compris en ce qui concerne les droits de brevet, ne peut être déduite de ce fait pour les cas individuels. Il n'est pas exclu que ce produit contienne des particules < 0,1 μm. Il incombe à tout utilisateur de ce produit de déterminer si les produits Sudarshan conviennent à son application particulière et de s'assurer que les droits de propriété, les lois et la législation en vigueur sont respectés.