PIGMENTO AMARILLO 97/ HP AMARILLO 1636

PIGMENTO AMARILLO 97/ HP AMARILLO 1636

C.I.NO.: PY97

Ventaja: Amarillo FGL

Aplicación principal recomendada: Recubrimientos al agua, Recubrimientos industriales

Descripción

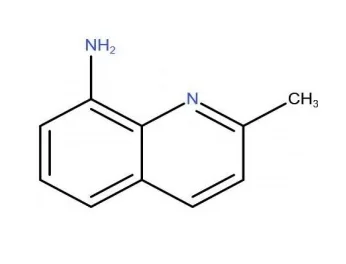

Descripción del producto -PY97

HP YELLOW 1636 (PIGMENT YELLOW 97) es un tono amarillo medio, más resistente a la mayoría de los disolventes orgánicos que los demás. Sus propiedades de solidez a la migración también son superiores. También tiene más resistencia al calor y propiedades muy resistentes a la luz y duraderas. Se recomienda principalmente para acabados industriales, pinturas al agua, tintas de impresión y también en plásticos, préstamos de color, etc.

Aplicación recomendada

Recubrimientos: recubrimientos al agua, recubrimientos industriales, recubrimientos para madera

Plásticos: PE, PP, PVC, EVA, ABS

Tintas de impresión: tintas offset, tintas base disolvente, tintas base agua

Datos técnicos

| Información sobre el producto | ||||

| Tipo químico | AZO | Nº CAS. | 12225-18-2 | |

| C. I. Nombre | Pigmento Amarillo 97 | EINECS / ELINCS NO. | 235-427-3 | |

| C. I. Constitución n. | 11767 | Fórmula química | C26H27ClN4O8S | |

| Rendimiento técnico | ||||

| Sombra completa | Tinte | |||

| Resistencia a la intemperie | 5 | 5 | Estabilidad térmica °C | 220°C |

| Solidez a la luz | 8 | 8 | ||

| Propiedades físicas | ||||

| Forma física | Polvo | Resistencia al ácido | 5 | |

| Densidad específica (g/cm3): | 1.40 ± 0.1 | Resistencia a los álcalis | 5 | |

| Superficie específica (㎡/g): | 26 | Resistencia a la migración PVC | 5 | |

| Absorción de aceite | 40 | Aplicaciones de bajo alabeo | Adecuado | |

| Valor pH | 6.5 ~ 8.5 | |||

| Materia volátil | 1% máx | |||

| Embalaje | ||||

| 25kgs/Bolsa 400kgs/Palet | ||||

| Almacenamiento | Vida útil | 5 años | ||

| Debe almacenarse en un lugar fresco, seco y ventilado. | ||||

| TRANSPORTE | ||||

| Evite la inversión, la luz solar, la humedad y los golpes. Evite dañar el embalaje. | ||||

- Solidez a la luz: El índice de solidez a la luz se evalúa en la escala de 1 a 8 de Blue Wool, en la que 1 = ‘deficiente’ y 8 = ‘excelente’.

- Estabilidad al calor: Los valores de estabilidad al calor dados indican la temperatura máxima a la que el pigmento puede ser estufado durante 10 min. a plena sombra y en reducciones sin sufrir ningún cambio significativo de tonalidad.

- Absorción de aceite: La absorción de aceite se determina sobre la base de la norma EN ISO 787-5 y se indica en g de aceite de linaza por 100 g de pigmento.

- Sangrado con disolvente: El sangrado en disolventes se prueba utilizando los grados de polvo y la calificación visual dada en 1 a 5 Escala de grises.

donde 1 = ‘Hemorragia intensa’ y 5 = ‘Sin hemorragia”

Descargo de responsabilidad - La información facilitada en esta ficha técnica se basa en el estado actual de nuestros conocimientos y pretende ser una descripción general de nuestros productos y sus posibles aplicaciones. Debido a la multitud de formulaciones, condiciones de producción y aplicación, todos los datos mencionados deben ajustarse a las circunstancias del procesador. De este hecho no pueden derivarse responsabilidades, incluidas las relativas a derechos de patente, para casos individuales. No se puede descartar que este producto contenga partículas < 0,1 μm. Cualquier usuario de este producto es responsable de determinar la idoneidad de los productos de Sudarshan para su aplicación particular y de asegurarse de que se respetan los derechos de propiedad y la legislación vigente.