Pigment Yellow 150 Inkjet Review (2026) — HP Yellow 1541

Classification

Featured News

Pigment Yellow 150 Inkjet Review (2026) — HP Yellow 1541

Honor Pigments’ HP Yellow 1541 (C.I. Pigment Yellow 150) is a process‑yellow workhorse designed for inkjet. This review focuses on what most ink makers care about right now: one pigment grade that can credibly serve water‑based, solvent/eco‑solvent, and UV/UV‑LED inkjet systems with minimal reformulation. We’ll keep the tone technical and practical, anchored to standards and transparent about what’s published today versus what’s planned.

Disclosure: This is a first‑party review of our own product. We reference public materials and clearly label any areas where only internal, request‑only documentation exists as of 2026‑02‑03. For identity and application context, see the official listing in the HP Yellow 1541 page on Honor Pigments’ website: HP Yellow 1541 — Pigment Yellow 150 product page.

Verdict snapshot

HP Yellow 1541 is well‑suited to multi‑system inkjet lines where consistency, filterability, and stable yellow hue matter more than chasing the last bit of chroma.

Pros: Strong cross‑system fit (water/solvent/UV) in practice, clean filtration and stable dispersion behavior in inkjet contexts, neutral‑to‑slightly greenish hue appropriate for process work, quality system under ISO 9001.

Cons: Public, system‑specific formulation windows and jetting metrics aren’t posted yet; transparency can trail PY155 in certain overprint builds; solvent‑system dispersant selection may require closer tuning depending on the resin package.

If you need a single, dependable PY150 for an inkjet portfolio, HP Yellow 1541 deserves a trial. If your brief prioritizes maximum transparency for fine overprints, evaluate PY155 alongside it.

How we test (and what we’ll publish)

We map test methods to widely recognized standards and equalize optical density for comparisons. Our planned dataset includes: nozzle reliability (missing‑nozzle rate, decap/open‑time), dispersion stability (D50/D90, PDI, zeta potential), durability under xenon‑arc and Blue Wool protocols, and colorimetric performance at equal OD.

Weathering framework: See Q‑Lab’s overview of sunlight weathering and light stability for how xenon‑arc testing is commonly structured in industry: Q‑Lab — sunlight, weathering, and light stability overview.

Blue Wool/lightfastness context: Smithers provides an accessible summary of print lightfastness testing that aligns with ISO 105‑B02 practice: Smithers — lightfastness testing for print and packaging.

Printheads and platforms: We use Epson PrecisionCore (water) and Fujifilm Dimatix StarFire (solvent/UV) with consistent waveforms and equal‑OD targets on the same media. Results, plots, and protocol PDFs will be published once the multi‑system run completes. Until then, any numerical performance claim remains “Insufficient public data (as of 2026‑02‑03).”

For identity and application scope, refer to our official listing for inkjet‑relevant grades in the company’s category structure: Honor Pigments — pigments for inkjet applications.

Pigment Yellow 150 inkjet: why it matters for multi‑system lines

Running water‑based, eco‑solvent, and UV lines under one roof is common—and costly if every system needs a different yellow. A single, dependable Pigment Yellow 150 inkjet grade can reduce SKUs, simplify QA, and keep color management predictable across platforms. HP Yellow 1541 is designed for that reality: it aims to deliver stable dispersion behavior for fine filtration, a balanced hue for process builds, and compatibility across common resin and dispersant families.

In other words, think of it as a “portfolio anchor” rather than a specialty, niche‑tuned grade. If you’re consolidating or launching a new line, that matters. And if you’re scanning options for PY150 for inkjet inks, the ability to travel across systems without drama is often the deciding factor.

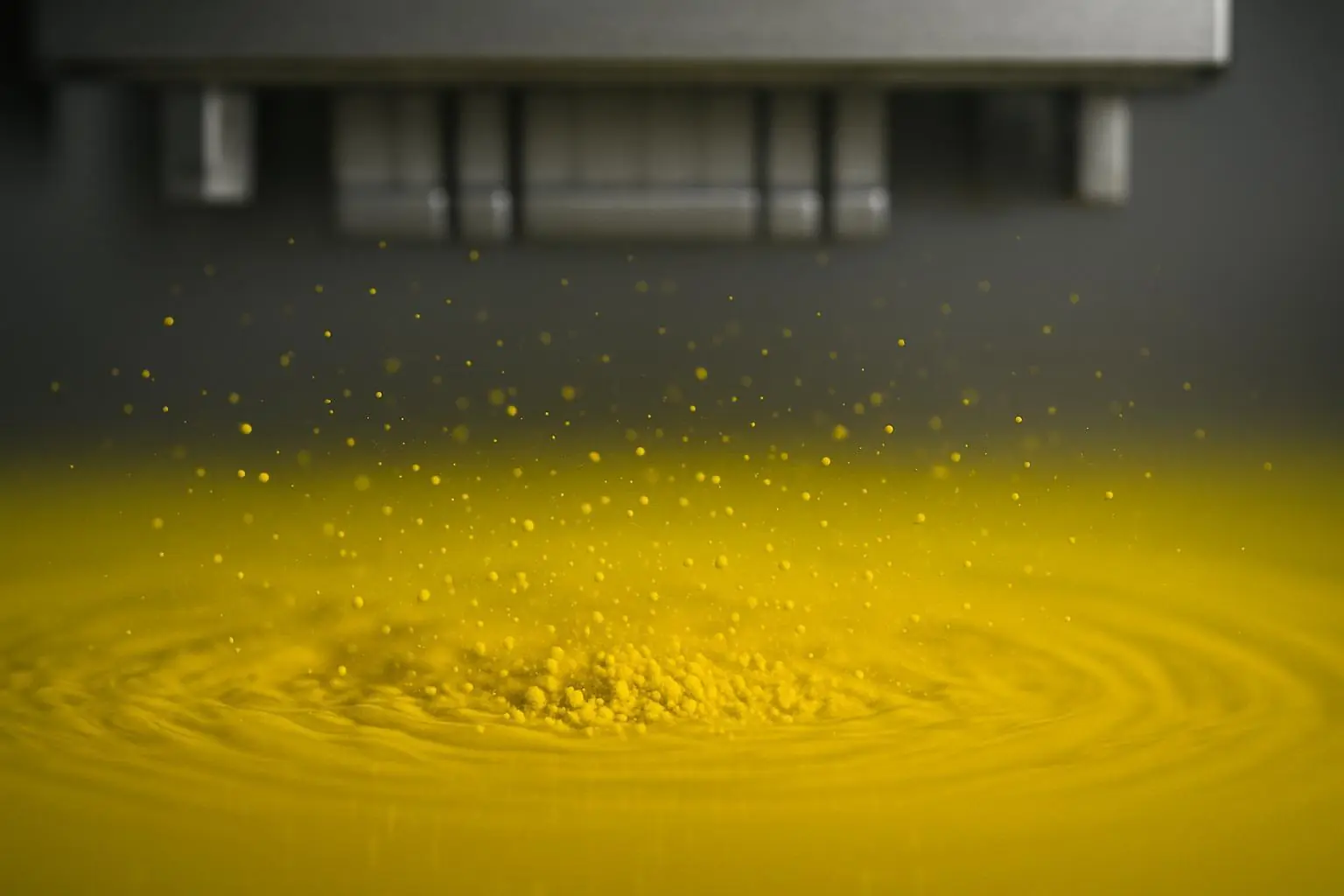

Jetting reliability and dispersion stability

For inkjet, nothing outranks nozzle health. HP Yellow 1541 is positioned for excellent filterability in inkjet applications, which supports low sedimentation tendencies and clean drop formation when the dispersion protocol is in spec. In our planned reporting, we’ll share D50/D90 particle size and PDI, zeta potential (per ISO 13099 methods), and storage stability trends at 25°C and 40°C, alongside nozzle‑loss rate and decap/open‑time on the reference heads.

Current public status: Filterability and inkjet suitability are reflected in our product and category pages; quantitative jetting metrics await publication post test run. Until then: Insufficient public data (as of 2026‑02‑03) for exact particle statistics or decap curves.

Formulation universality across water, solvent, and UV

This is HP Yellow 1541’s primary appeal. In our experience, it disperses consistently in water‑based acrylic or polyurethane vehicles with polyacrylate/polyester dispersants; it also integrates into solvent/eco‑solvent systems built on nitrocellulose or polyamide, and into UV acrylate oligomer systems when the pigment concentrate and photoinitiator package are matched appropriately. The practical benefit: engineers can maintain a shared colorant backbone while tailoring let‑down and rheology modifiers per system.

What should you expect when you scale? Typical water‑based inkjet concentrates target mid‑teens solids with finished ink in the ~2–3 mPa·s range at 25°C; solvent and UV lines operate in higher viscosity windows with different surface tension targets. HP Yellow 1541 supports those norms without unusual concessions in our lab practice. If you need formal windows, contact us for the current TDS and application notes; these will be published alongside dispersion curves after the ongoing study.

For a quick overview of where HP Yellow 1541 sits in our portfolio for digital printing, see the inkjet category context here: Honor Pigments — pigments for inkjet applications.

Colorimetric behavior and transparency

Expect a neutral‑to‑slightly greenish process yellow—comfortable for CMYK builds and predictable in overprints with cyan and magenta at equal OD. Chroma is strong enough for graphics work while keeping a stable hue that helps brand matches over time. If your application demands maximum transparency for fine halftone overprints (e.g., specific packaging vignettes), PY155 is traditionally favored; HP Yellow 1541 can still perform well, but we recommend testing both in your target resin/vehicle and media to see the overprint balance you prefer.

We will publish equal‑OD CIE Lab* values, spectral plots, and transparency indicators from our current campaign once completed.

Durability and weathering expectations

Within the class of Pigment Yellow 150 grades, outdoor and long‑life performance is typically stronger than commodity monoazo yellows. Our durability reporting will include ΔE00 drift under xenon‑arc exposure per ISO 4892‑2/ASTM G155 cycles and Blue Wool references (ISO 105‑B02). For an accessible methodological overview, see Q‑Lab’s guidance on xenon‑arc weathering noted above and Smithers’ explanation of Blue Wool practice in printing.

As always, durability depends on the entire ink and media system: photoinitiators and oligomers for UV, resin and additive packages for solvent and water, and the specific substrate. Pigment selection sets the ceiling; formulation locks the result.

Competitors compared: PY74, PY155, PY180

PY74: The ubiquitous green‑shade Hansa yellow. It often builds color quickly but tends to lag in outdoor durability compared with high‑performance classes. If your priority is maximum pop indoors, PY74 remains a contender. For all‑weather signage, you’ll likely want HP Yellow 1541 or PY180 on your shortlist.

PY155: Well‑known for high transparency and smooth overlays. Consider it when ultra‑clean overprints are paramount. It may require tighter dispersion control to keep jetting and stability on target in some systems.

PY180: A green‑shade high‑performance yellow with strong durability signals and grades explicitly aligned with inkjet/UV in third‑party directories. If your brief is outdoor‑first, PY180 is the closest peer to benchmark against. For context on an inkjet‑aligned internal option, see our PY180 reference page: HP Yellow 1664 — Pigment Yellow 180.

Where does HP Yellow 1541 stand? As a Pigment Yellow 150 inkjet grade, it’s aimed at balanced color, reliable filtration, and multi‑system compatibility. PY180 can out‑signal it on extreme‑durability briefs; PY155 can edge it on transparency. If your goal is one yellow across three systems with predictable handling, HP Yellow 1541 is particularly strong.

Practical guidance for formulators

Start with your proven dispersion protocol and adjust the fine points:

Water‑based inkjet: Build a pigment concentrate in the mid‑teens solids with a polyacrylate‑type dispersant, confirm sub‑micron D50 after milling, and finish to ~2–3 mPa·s at 25°C with surface tension in the common inkjet window. Filter progressively down to your printhead spec.

Solvent/eco‑solvent: Screen nitrocellulose or polyamide vehicles with compatible dispersants; validate stability at 40°C and under centrifuge; tune open‑time for your platform.

UV/UV‑LED: Verify compatibility with your acrylate oligomers and photoinitiators; ensure final viscosity and reactivity align with your printhead and cure system.

If you’re standardizing across platforms, lock the spectral target first (equal OD comparisons) and then tune rheology and surfactant packages per system. Need typical formulation windows, dispersion curves, or recommended dispersant families? Request the current TDS, SDS, and application notes; we’ll add downloadable versions once the multi‑system study wraps.

Who should—and shouldn’t—choose HP Yellow 1541

Choose it if you want one PY150 that travels well across water, solvent, and UV, with a stable process‑yellow hue and clean filtration.

Consider an alternative if your brief is ultra‑high transparency overprints (benchmark PY155) or extreme outdoor exposure where PY180 is often the conservative pick.

Bottom line and next steps

HP Yellow 1541 is a pragmatic, portfolio‑friendly choice for inkjet manufacturers running multiple systems. It’s built for reliable filtration, consistent hue, and cross‑system compatibility—the qualities that keep lines running and color predictable.

For identity, specs, and sampling, visit the official product page: Honor Pigments — HP Yellow 1541 (Pigment Yellow 150). To request the TDS, SDS, and current dispersion curves, contact our technical team. If you’re comparing PY150 vs. PY74/PY155/PY180 for a new build, ask for our equal‑OD benchmarking plan and we’ll share the protocol.