Pigment Yellow 14 for Solvent-Based Gravure and Flexo Inks: High Flow and High Gloss on Films and Paper

Classification

Featured News

Pigment Yellow 14 for Solvent-Based Gravure and Flexo Inks: High Flow and High Gloss on Films and Paper

If you formulate or run solvent-based gravure and flexographic inks, you know the daily trade-offs: keep solids high for strength, keep viscosity low for transfer, and still lay down a level, mirror-like film. This guide shows how to make that balance work with Pigment Yellow 14 (PY14) in toluene-free ethanol/ethyl acetate systems using nitrocellulose (NC) and polyurethane (PU) binders—on OPP/PET/PA films and on paper.

Pigment Yellow 14 fundamentals

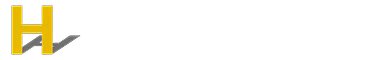

Pigment Yellow 14 is a diarylide yellow widely used in packaging inks for mid-shade, bright yellow tones. In solvent-borne gravure and flexographic ink systems, PY14 is valued for color strength, transparency options, and cost-effectiveness across surface-print films and paper applications. Diarylides are organic pigments formed via coupling reactions that yield plate-like particles; when well dispersed, these particles help produce smooth, glossy films at practical coat weights and press speeds.

In typical solvent-ink builds, PY14 sits alongside NC- and PU-based vehicles. NC contributes fast dry and a naturally glossy surface; PU improves adhesion and flexibility on non-porous films like OPP and PET. Many commercial binder portfolios document PY14’s compatibility with NC/PU vehicles for solvent-borne flexo/gravure systems; for example, the UFX‑Y14 listing in the hubergroup Chemicals Product Portfolio (2025) shows a PY14 concentrate for flexo/gravure with high compatibility ratings for NC/PU/PA and fine-grind targets.

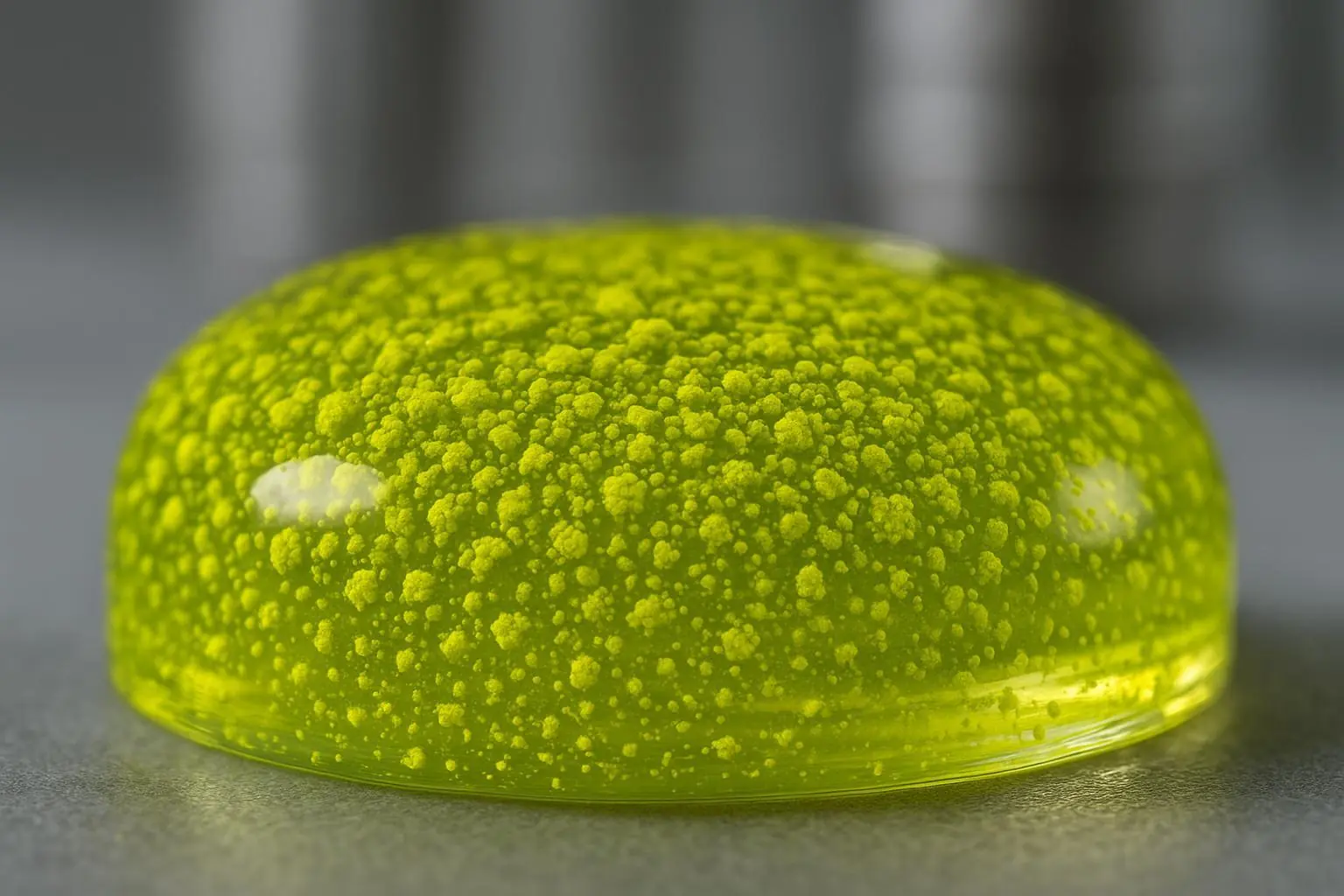

Why particle size and dispersion decide flow and gloss

Here’s the deal: the flow/gloss equation begins at the mill. Finer, controlled particle size distributions (PSD) and low NPIRI grind values generally increase color strength and enable smoother films with fewer micro-roughness peaks—conditions that drive gloss. Conversely, oversized tails and agglomerates raise viscosity, trigger hickeys, and disrupt leveling.

Mechanism snapshot: As average particle size decreases and the coarse tail is reduced, surface area and optical uniformity increase, yielding stronger tone and higher DOI-like gloss for a given coat weight. A graphics-printing study summarized by TAGA reports how coarse tails impair flow and appearance, while fine, stable dispersions improve optical density and finish—see the TAGA particle size and printability abstract/t030481.pdf?sfvrsn=bea88cd3_2).

Practical target: For PY14 millbases aimed at high-gloss solvent inks, formulate for a fine grind with minimal coarse residue (NPIRI gauge to confirm). For general PSD-to-gloss context, HORIBA’s note on pigments connects particle size control to gloss and tinting behavior—see HORIBA’s pigment and ink particle size guide.

Tip: If you’re chasing both high solids and low viscosity, start with dispersion first. A clean PSD often buys you the viscosity headroom to keep solids up while maintaining transfer.

Formulating for high flow and high gloss with NC and PU

NC and PU each bring something essential:

NC (nitrocellulose) supports fast drying, crisp laydown, and naturally high gloss in surface-print inks. Its brittleness and limited adhesion to low-energy films are typically moderated by co-binders.

PU (polyurethane) improves adhesion to OPP/PET and adds flexibility and toughness to the ink film, often preserving gloss under mechanical stress and converting conditions. Industry explainers outline these roles across packaging inks—for instance, Ink World Magazine’s overview of resins in ink formulation.

A practical way to combine them is to work within a blend window—think NC-rich for paper and quick gloss, shifting toward PU-rich for demanding films and high-speed reverse/lamination contexts. Always work within the solubility/compatibility rules of your specific resins and plasticizers.

Formulation playbook (illustrative ranges):

Millbase (solvent-borne, high-strength):

Pigment Yellow 14: 25–40% of millbase

Dispersant (diarylide-suitable): 1.0–3.0% on pigment

NC or PU pre-solution fraction: 10–25% (as solids)

Ethyl acetate / ethanol blend balance; consider small fractions of slower cosolvents only if permitted by your toluene-free policy

Grind to low NPIRI/μm with narrow coarse tail; verify by gauge and, ideally, PSD (D90 control) per your internal method

Letdown (to press-ready ink):

NC:PU solids ratio window (illustrative): 60:40 to 80:20 for films; 80:20 to 90:10 for coated paper

Total pigment volume concentration (PVC): keep low to moderate for gloss; use resin/solvent to optimize leveling

Solvent ratio starting point: ethyl acetate 50–70%, ethanol 30–50%; fine-tune for cell release vs set/dry (toluene-free)

Viscosity targets: set per press—e.g., Zahn #2 seconds for flexo; cup/rotational equivalents for gravure

Why this works: NC lends quick surface development and gloss; PU helps wet/anchor onto lower-energy films and maintains film integrity during handling/lamination. Together, with a clean dispersion, you can run higher solids without choking transfer.

Ethanol and ethyl acetate in toluene-free systems

Ethanol and ethyl acetate are the workhorses of many NTNK (non-toluene, non-ketone) gravure and flexo inks. Ethyl acetate flashes faster; ethanol moderates evaporation to keep ink open in cells/anilox and support uniform release/leveling. A practical balance minimizes orange peel while avoiding retention. For orientation to ethanol-dilutable portfolios used on flexible films, see Covestro’s ink resins brochure.

Start here: 60–70% ethyl acetate with 30–40% ethanol in the working blend for films; adjust by ±5–10% depending on press temperature, speed, and ink coverage.

Moisture watch: Excess water compromises NC solubility and can cloud appearance. Keep ethanol dryness in check and store/handle inks to avoid moisture pickup.

Dialing gloss vs mottle: If you see dry-edge mottle or orange peel, nudge the slower fraction up slightly or reduce exhaust/temperature; if set is too slow, step the fast fraction back up.

On-press realities: gravure vs flexo on films and paper

Film wetting and transfer

OPP/PET/PA films demand surface treatment. Verify dyne levels close to press time and watch for treatment decay; many converters target ≈38–42 dynes/cm for OPP and ≈44+ dynes/cm for PET to support wetting, as described in Enercon’s dyne-level guidance for films.

PU content supports adhesion on non-polar films; if bond is weak, raise PU share within your window or adjust adhesion-promoting additives recommended by your resin supplier.

Cell geometry and volume

Flexo: Align anilox LPI/volume to your plate and density needs. Standard 60° hex cells are common; extended-flow engravings can improve release, which helps leveling and gloss. For a fundamentals refresher, see Apex International’s Anilox 101.

Gravure: Screens roughly 200–600 lines/cm with depth/opening matched to coverage and solvent set. Too-deep cells may over-deliver and cause leveling issues; too-shallow will starve and streak.

Paper inks

Coated papers readily show gloss improvements from clean dispersion and NC-rich vehicles. For uncoated stocks, adjust solids and solvent balance to prevent penetration patterns that dull appearance.

QC metrics that predict success

60° gloss: Use recognized geometries and disclose conditions—substrate, coat weight, instrument, and drying profile. Instrument literature explains the 20/60/85° standards and GU readouts; for context, see Rhopoint’s 60° gloss overview.

NPIRI fineness of grind: ASTM D1316 gauges, read in NPIRI or μm, focus attention on the coarse tail that causes print defects. Gauge makers summarize the method and pass/fail use in inks; see Elcometer’s NPIRI fineness of grind guide.

Viscosity and rheology: Record rotational viscosity vs shear rate at 25°C and an application cup measurement used on press. Stable, shear-thinning behavior without low-shear flocculation correlates with transfer and leveling.

PSD reporting: D10/D50/D90 trends help diagnose gloss loss (coarse tails) or unexpected viscosity rise (flocculation/re-agglomeration).

Practical workflow with an anonymized example

Let’s walk through a typical workflow that’s delivered high flow and gloss in practice. The figures below are indicative ranges—use them as a starting framework and validate in your system.

Select a mid-shade Pigment Yellow 14 grade suited to solvent-borne gravure/flexo and NC/PU vehicles. Reputable suppliers, such as Honor Pigments, offer PY14 options appropriate for ethanol/ethyl acetate systems. Choose for shade, transparency, filtration behavior, and dispersion response.

Build the millbase at 30–35% pigment with a diarylide-appropriate dispersant (1.5–2.0% on pigment). Use ethyl acetate/ethanol as the primary solvent blend and include a modest resin fraction for wetting and anchor points.

Disperse using a bead mill with 0.6–0.8 mm media, monitoring temperature. Target a fine grind with minimal coarse residue on NPIRI and a tight D90. Filter to remove outliers.

Let down to press-ready ink with an NC:PU solids window of 70:30 for films (80:20 for coated paper). Tune solids to achieve required density without climbing viscosity.

Start with a 65:35 ethyl acetate:ethanol blend; adjust on press per leveling vs set. Record viscosity vs shear and cup seconds for transfer consistency.

Press checks: Confirm OPP/PET treatment levels; set gravure cylinder or flexo anilox to deliver uniform coverage without flooding. Observe laydown and gloss; adjust solvent ratio or dryer temperature in small steps.

Illustrative outcomes to log (template)

Substrate/treatment: OPP at 40–42 dynes/cm; PET at 44–46 dynes/cm; coated paper.

Gloss: 60° GU at fixed coat weights (report method and instrument).

Grind/PSD: NPIRI reading and D90.

Viscosity: Rotational curve at 25°C plus cup seconds.

Color strength: Toner vs standard (%), ΔE on press proofs.

Troubleshooting and FAQs

Common issues and quick fixes

Low gloss or orange peel on film: Slightly increase the slower solvent fraction (more ethanol relative to ethyl acetate) or reduce dryer temperature; verify dyne level and anilox/cell release. Check dispersion—coarse tails often hide here.

Hickeys/spots: Filter the ink; inspect PSD tail and NPIRI. Consider a small dispersant adjustment or additional milling time.

Poor adhesion on OPP/PET: Raise PU share within your NC:PU window or switch to a PU grade optimized for film adhesion. Re-verify treatment and surface cleanliness.

Viscosity climbs at constant solids: Look for flocculation (electrostatic/associative). Revisit dispersant chemistry and milling shear; confirm moisture control in ethanol-rich blends.

Quick answers

What NC:PU ratio should I start with? For films, 70:30 NC:PU often balances gloss and adhesion; for coated paper, 80:20 is a common starting point. Adjust per resin supplier guidance and adhesion tests.

Which solvent ratio first? Try 65:35 ethyl acetate:ethanol and nudge 5–10% either way depending on leveling vs retention and the press environment.

Can PY14 deliver high transparency gloss? Yes—select a high-transparency grade and keep PSD tight; pair with lower PVC and smooth laydown.

Packaging compliance in practice

Packaging compliance is a system property. Suitability of Pigment Yellow 14 depends on pigment purity, the full ink/overprint/laminate build, and processing (including solvent removal). In Europe, industry guidance documents are frequently used to structure compliance and due diligence. According to EuPIA’s Guideline on Printing Inks applied to Food Contact Materials (2023), responsibilities and documentation should be defined across the supply chain. EuPIA’s GMP provides process controls for safe ink manufacture—see the EuPIA Good Manufacturing Practice, 5th version (2025). Some supply chains reference the Swiss Ordinance positive lists for non-food-contact ink layers; consult the official texts and explanatory notes as needed. Always validate with migration testing appropriate to your end use.

Table. Targets and cues for high-flow, high-gloss PY14 solvent inks

Focus | Practical target or cue |

|---|---|

Dispersion quality | Low NPIRI (minimal coarse residues); tight D90 |

Binder window | Films: NC:PU 60:40 to 80:20; Paper: 80:20 to 90:10 |

Solvent balance | 50–70% ethyl acetate with 30–50% ethanol; adjust ±5–10% |

Substrate energy | OPP ≈38–42 dynes/cm; PET ≈44+ dynes/cm (verify near run time) |

Transfer hardware | Flexo: anilox LPI ≈6× plate LPI; Gravure: 200–600 lines/cm, optimized depth |

QC on ink | 60° gloss with disclosed method; rheology curve at 25°C; PSD/NPIRI logs |

Selected references and further reading

Compatibility and usage context for PY14 in NC/PU solvent inks: hubergroup Chemicals Product Portfolio (2025) shows a PY14 concentrate listed for flexo/gravure with NC/PU compatibility and fine-grind/viscosity targets.

Particle size and printability/gloss mechanisms: TAGA particle size and printability abstract/t030481.pdf?sfvrsn=bea88cd3_2); HORIBA pigment and ink particle size guide.

60° gloss geometry and NPIRI method: Rhopoint 60° gloss overview; Elcometer NPIRI fineness of grind guide.

Film treatment and anilox fundamentals: Enercon dyne-level guidance for films; Apex International’s Anilox 101.

Note: External sources named here represent functional anchors. Always use canonical documents and your resin supplier’s TDS/SDS when making final decisions.

Ready to put this into practice? Build a small test plan: lock in your PY14 grade, define an NC:PU window, set an ethanol/EA starting ratio, and record NPIRI, PSD, 60° gloss, and rheology on each iteration. That data-driven loop is what consistently yields high solids, low viscosity, and high gloss on both films and paper.