Pigment Yellow 13 for Flexo & Gravure Inks: Properties, QC, Compliance

Classification

Featured News

Pigment Yellow 13 for Flexo & Gravure Inks: Properties, QC, Compliance

If you formulate or qualify packaging inks, you’ve almost certainly worked with Pigment Yellow 13. This diarylide workhorse delivers bright, clean hues and high tint strength in both flexographic and gravure systems—provided you manage dispersion, viscosity, and transparency with intent. This guide distills what matters most for solvent- and water-based inks, shows how to prove batch-to-batch color consistency with disciplined QC, and maps the compliance checkpoints you need to document.

Quick reference: Pigment Yellow 13 at a glance

Pigment performance depends on grade, vehicle, and test method. Treat the ranges below as representative starting points; confirm with your supplier’s TDS and in-house testing. Industry directories and ink pigment brochures list PY13 as a standard choice for flexo/gravure systems and note workable heat and lightfastness ranges in printing conditions.

Attribute | Typical range / notes | Evidence context |

|---|---|---|

Identity | Diarylide yellow, C.I. 21100 (often referenced as C.I. Pigment Yellow 13) | Listed for ink use in the Pigments.com directory and a 2023 pigments-for-inks brochure |

Hue & strength | Green-shade yellow; high tint strength in low-viscosity inks | Noted across directories and brochures |

Lightfastness | Full shade ~4–6; tints ~3–4 (printing films) | Representative directories and brochures report these bands |

Heat stability | ~180–200 °C depending on system/time | Ink brochures and directories indicate this envelope |

Resistance | Generally good solvent/chemical resistance in inks | Inks-focused brochures and directories |

Common vehicles | Solvent NC/PA/PU for flexo/gravure; water-based acrylic/PUD | Standard ink practice sources |

References in context: see the ink pigments brochure from Vibrantz (2023) and the Pigments.com directory for ink suitability and typical ranges.

Chemistry and behavior in inks

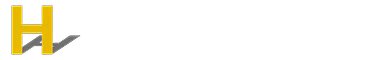

Pigment Yellow 13 belongs to the diarylide family. In ink films it presents as finely dispersed solids whose particle-size distribution drives both transparency and gloss. Finer, narrower distributions increase transparency and color strength—critical in flexo and gravure where low viscosity and thin films dominate. Compatibility with common binders is well established:

Solvent systems: nitrocellulose (NC), polyamide (PA), and polyurethane (PU) vehicles support fast drying and adhesion on films and papers. PY13 disperses efficiently in these systems when paired with suitable wetting/dispersing additives.

Water-based systems: acrylic emulsions or polyurethane dispersions (PUDs) are common. pH control and co-solvent choice influence stability and lay.

The trade-off to keep in mind: pushing particle size too fine can increase surface area and thicken the ink; you’ll balance transparency targets against viscosity and press latitude.

Performance in flexo vs gravure, solvent vs water

Gravure tends to run lower viscosity and relies on clean release from engraved cells; PY13’s high strength makes it a staple for solids and process tints when dispersion is optimized.

Flexo (solvent or water) benefits from PY13’s brightness in high-linecount anilox work. Managing transparency is key to avoid over-covering fine screens.

Solvent systems (EtOH/IPA/ethyl acetate/ethers) typically yield higher gloss and faster set. Water-based systems demand more attention to pH/amine balance and foam control but can match color strength with the right dispersants.

Think of PY13 as a flexible building block. With proper grind and rheology, you can hit clean greenshade yellows that track closely in production.

Formulation and dispersion workflow

Below are general, non-proprietary “skeletons.” Always tune to your resin, substrate, and press.

Solvent flexo/gravure millbase (example proportions by weight):

Pigment Yellow 13: 20–30%

NC or PU resin solution (in EtOH/EtOAc): 40–55%

Dispersant/wetting aid (diarylide-suitable): 1–3%

Solvent balance (EtOH/EtOAc/ether): to 100%

Target grind: Hegman ~5–6; many shops aim for sub‑micron D50 with bead milling for maximum transparency.

Water-based flexo millbase (example):

Pigment Yellow 13: 15–25%

Acrylic emulsion or PUD: 35–50%

Anionic/nonionic dispersant: 1–3%

Co-solvent (e.g., DPNB) and water; pH 8.0–9.0 with amine; defoamer as needed

Target grind similar to solvent systems; verify stability across freeze–thaw and storage.

Process notes:

Premix under high shear to fully wet the pigment before bead milling; select media size roughly 10–100× the desired final particle size and keep temperature under control to prevent flocculation. See Hockmeyer’s guidance on ink dispersion scale-up for media selection and energy input.

Record viscosity after temperature normalization; small solvent ratio changes (e.g., ethanol/ethyl acetate) can fine-tune flow and leveling without altering shade.

Viscosity and on-press rheology targets

Low-viscosity behavior with predictable shear thinning is the goal.

Flexographic inks: many converters hold water-based inks around 22–32 s on a #2 Zahn cup; solvent-based windows often fall in a similar or slightly broader range, depending on anilox and speed. For a production‑focused explainer of flexo viscosity windows and pH control, see this 2024 article for plant teams.

Gravure inks: typically lower—often ~15–25 s on #2 Zahn—so they drain/transfer cleanly from cells at speed. For gravure rheology fundamentals and the role of shear‑rate dependence in transfer, consult a peer‑reviewed study on gravure inks and a technical overview of gravure coating behavior.

Treat these as starting windows influenced by resin system, temperature, solvent blend, anilox cell volume/line count, and press speed. Rheology studies of gravure transfer reinforce the importance of controlled shear dependence for smooth lay.

Lightfastness, heat stability, and migration controls

Lightfastness: Expect stronger performance in masstone (often ~4–6 on the Blue Wool scale) and a drop in tints (commonly ~3–4). Thinner films and co‑resins can accelerate fading. Mitigate by increasing film thickness where tolerable, choosing more light‑stable co‑pigments for blends, and adding UV absorbers/HALS in demanding exposures.

Heat stability: PY13 generally withstands ~180–200 °C in typical ink processes depending on dwell; watch IR dryers and lamination temperatures. Validate in your exact line conditions.

Migration/set‑off: Packaging applications require attention to residual solvents, plasticizers, and oligomers. Design for low migration using appropriate binders/additives and verify with standardized migration testing (simulants, time/temperature) for the intended end use.

Representative ranges and ink-suitability context are summarized in an ink pigments brochure and a pigments directory that both list PY13 for flexo/gravure uses.

Quality control and batch consistency

If your differentiator is consistency, define it in your methods—not just in adjectives. Here’s a disciplined approach you can implement with your suppliers and in-house labs.

Instrument setup

Use a spectrophotometer compliant with ISO 13655. Select the appropriate M-condition (commonly M1) and fix illuminant/observer—for packaging workflows, D50/2° is typical, but some programs work with D65/10°. Declare aperture size and backing (black or white) in the method. A readable overview of M‑standards and trade-offs is available from X‑Rite.

Reference and sampling

Maintain a master standard for each target shade. For every production lot, draw at least n ≥ 3 samples across the batch (start/middle/end). Measure spectral reflectance and compute both CIE Lab* and ΔE (preferably ΔE00).

Example acceptance rule (stringent internal target)

Average ΔE00 ≤ 0.8 to master; maximum ≤ 1.0 triggers review. Note: many commercial printing tolerances are looser (for example, solids within about 1.0 ΔEab between runs in a published flexography case), so ≤0.8 represents a rigorous internal supplier goal rather than an industry mandate.

Control and documentation

Maintain SPC charts for ΔE/Lab* drift; investigate when rules are violated. Include a Certificate of Analysis (COA) with instrument settings, spectral data (ideally a CxF file), sample positions, and traceability.

Sourcing tip: when qualifying a PY13 source, ask for recent SPC summaries and COAs with spectral data. Reputable suppliers can support this. For example, Honor Pigments lists PY13 among its offerings; when engaging any supplier, request documented colorimetric methods, batch targets, and corrective-action protocols to demonstrate consistency.

Regulatory and compliance essentials

ECHA/REACH: Verify current regulatory status via the European Chemicals Agency’s public Substance Information portal. Search by name or identifiers (e.g., CAS 5102‑83‑0) and review classification/labeling and dossier notes. Treat that page as the canonical reference and archive a copy in your compliance file at qualification time.

EuPIA Exclusion Policy (8th Ed., 2025): Printing-ink makers in Europe follow this policy to avoid certain hazard classes and explicitly listed substances. Diarylide pigments like PY13 aren’t named as exclusions in the policy text we reviewed; however, compliance still requires GMP discipline, documentation on primary aromatic amines where relevant, and overall formulation controls.

EN 71‑3 toy elements migration: The standard defines migration limits for 19 elements across material categories. For toy or toy‑packaging inks, suitability isn’t determined by pigment identity alone; it depends on the finished article’s migration under specified conditions. Always confirm with accredited lab testing for the intended end use and retain supplier declarations and test reports.

Authoritative resources for these checkpoints include the EuPIA Exclusion Policy (latest edition) and the ECHA Substance Information portal.

Troubleshooting matrix for Pigment Yellow 13 in flexo/gravure inks

Symptom | Likely cause | Practical fix |

|---|---|---|

Dull tint or loss of brightness | Coarse or broad particle-size distribution; flocculation; over‑reduction | Increase milling energy/optimize media; adjust dispersant level/type; verify solvent balance and letdown order |

Viscosity spikes after storage | Incomplete wetting; resin–dispersant mismatch; temperature swings | Rebalance dispersant; consider alternative wetting agent; control milling temperature; recheck resin solution solids |

Poor cell release in gravure | Viscosity too high at shear; solvent too slow; particle size too coarse | Lower viscosity within window; increase fast solvent fraction; push finer grind |

Set‑off or suspected migration | Residual solvent high; low‑migration design not followed | Extend drying/IR profile; switch to low‑migration binders/additives; run standardized migration tests |

Faster fading in tints | Thin films; high UV exposure; co‑resin effects | Add UV absorber/HALS; increase film thickness where possible; evaluate more light‑stable blend partners |

References and further reading

Ink pigments brochure outlining typical uses and properties for diarylide yellows in printing inks (Vibrantz, 2023): https://vibrantz.com/wp-content/uploads/2023/02/110-Ferro-Pigments-for-Inks_DIGITAL-BROCHURE_new-.pdf

Directory listing pigments recommended for inks, including PY13 (Pigments.com): https://www.pigments.com/wp-content/uploads/NA-Pigments-Directory.pdf

Ink dispersion scale-up and media selection best practices (Hockmeyer): https://hockmeyer.com/blog/articles/ink-dispersion-scale-up-from-the-lab-to-production/

Gravure printing with shear‑rate‑dependent inks (peer‑reviewed study, Cambridge “Flow”): https://www.cambridge.org/core/journals/flow/article/gravure-printing-with-a-shearratedependent-ink/9A68EDF6D66784CDA794E9018A3493F1

Practical viscosity windows and pH guidance for flexo production (SC Printing Ink, 2024): https://scprintingink.com/2024/11/21/understanding-water-based-printing-ink-viscosity-standards/

ISO 13655 M‑standards explainer and instrument setup (X‑Rite): https://www.xrite.com/page/learn-more-about-m-standards

EuPIA Exclusion Policy, 8th Edition (2025): https://www.eupia.org/wp-content/uploads/2025/04/Ed8_EP_final.pdf

ECHA public Substance Information portal (search PY13 identifiers): https://echa.europa.eu/substance-information

Closing

Pigment Yellow 13 remains a dependable yellow for flexo and gravure—so long as you control dispersion to the right particle-size envelope, hold ink rheology inside a validated window, and verify lot-to-lot color with a transparent, standards‑based QC method. Build your qualification kit with a defined colorimetric setup, SPC expectations, and compliance documents, and you’ll get clean, repeatable color on press without guesswork.