Pigment Red 48:2 for solvent-based inks in gravure printing — properties, resistance, and formulation considerations

Classification

Featured News

Pigment Red 48:2 for solvent-based inks in gravure printing — properties, resistance, and formulation considerations

Pigment Red 48:2 (PR48:2), also known as Calcium Red 2B (C.I. 15865:2), is a staple rubine-shade monoazo lake in solvent-based packaging inks. If you formulate nitrocellulose (NC) gravure reds for BOPP or PET, balance alcohol/ethyl acetate systems, or qualify inks for PU/PA laminations, you’ve likely weighed PR48:2’s color strength, gloss, bleed behavior, and cost-in-use against alternatives. This guide distills what matters in real production: where PR48:2 excels, where it needs risk controls, and how to set up dispersion, QC, and migration tests so the press run is as predictable as the lab.

Who this is for: ink formulators, QC/QA chemists, technical managers, and procurement engineers working on solvent-based gravure (and related flexo) inks for flexible packaging.

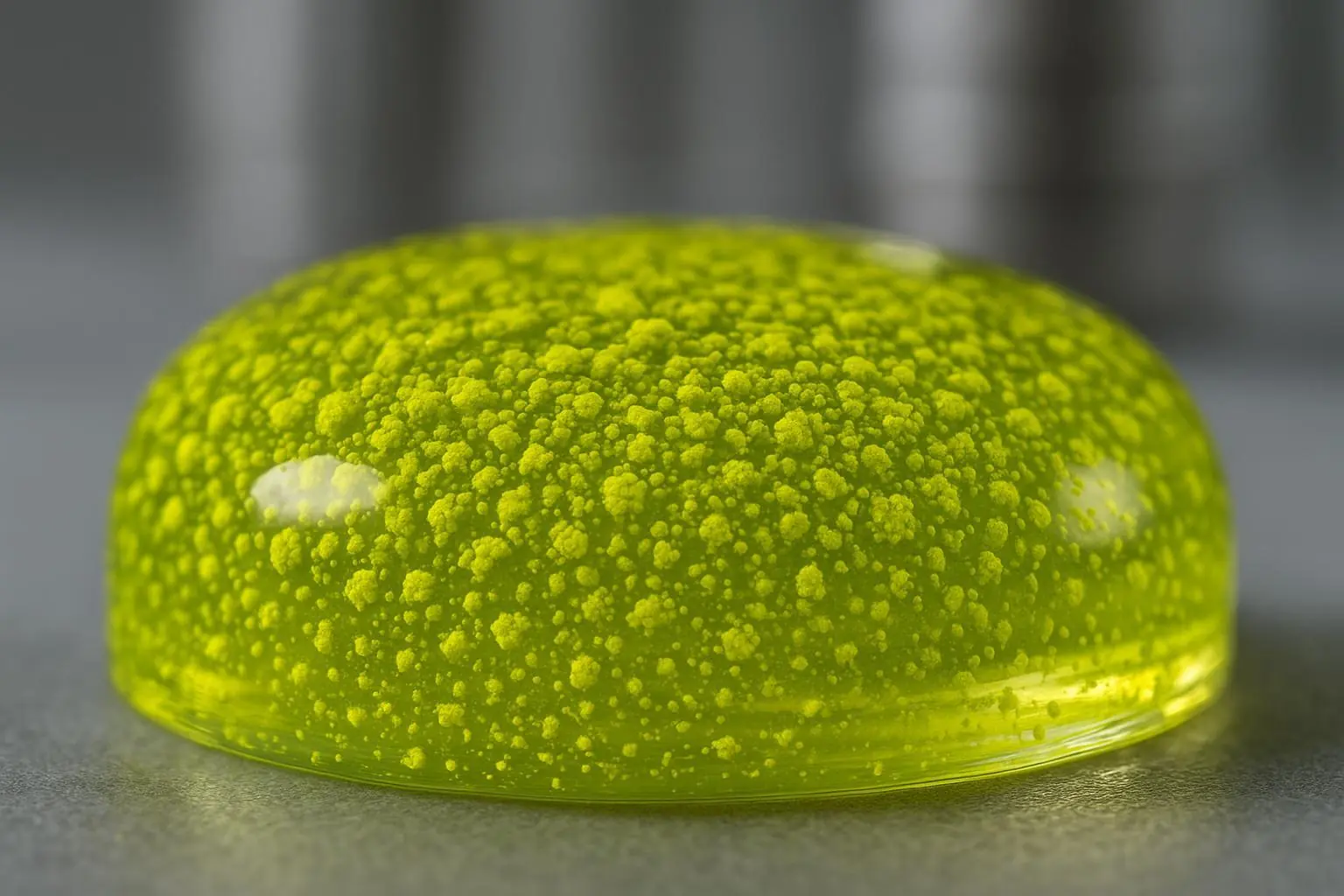

Identity and shade positioning

PR48:2 is the calcium salt of a Lithol Rubine monoazo pigment. In inks it typically presents as a bluish rubine shade, semi‑transparent, with high tinting strength and good gloss. Particle morphology and moderate oil absorption help flow and leveling in low-viscosity gravure vehicles. In day‑to‑day formulation, it’s the “workhorse rubine” for process reds, matches requiring a bluish bias, and vivid spot reds that still need clean overprints.

When sourcing or qualifying supply, ensure grade-level surface treatments and PSD are compatible with your solvent blend and NC backbone. For a concise view of pigment categories used in inks, see the printing-ink portfolio overview from Honor Pigments. This reference is provided neutrally for context.

Why Pigment Red 48:2 for solvent-based inks remains widely used

Formulators continue to specify Pigment Red 48:2 for solvent-based inks because it balances three practical levers:

Coloristic performance: strong tinting strength with a clean bluish rubine shade and semi‑transparency that supports high gloss in thin gravure films.

Resistance profile: generally good resistance to common packaging solvents (alcohols, esters, aromatics) when dispersed correctly and protected against flocculation; overprint bleed is typically moderate and must be managed by test method and formulation.

Cost‑in‑use: efficient milling to target fineness, compatibility with common NC vehicles, and high strength can reduce pigment loading for a given density.

Here’s the deal: PR48:2 isn’t the most bleed‑resistant option available, but with disciplined dispersion, solvent balance, and QC, it’s a reliable, economical choice for many NC gravure and lamination‑capable systems.

For solvent resistance context, directories and a representative TDS consistently position PR48:2 for solvent-based and offset inks, with strong performance in alcohols/esters/aromatics. See this summary in the DCL/DCC‑LANSCO technical document, where ethanol is rated very good, ethyl acetate excellent, and aromatics very good in typical scales: PR48:2 resistance properties — DCL/LANSCO 1482 TDS. Broader ink brochures echo this positioning; for example, Vibrantz’s pigments for inks overview describes rubine pigments with high intensity, gloss, and transparency.

Typical performance profile and what to verify in your lab

Because published, ink‑specific numeric data vary by grade and testing method, use the following as directional guidance and lock final values with your supplier’s TDS and in‑house tests:

Solvent/chemical resistance (qualitative expectations in solvent-based inks):

Alcohols (e.g., ethanol, IPA): very good

Esters (e.g., ethyl acetate): excellent

Aromatics (e.g., toluene/xylene proxies): very good

Ketones (e.g., MEK): good to very good

Aliphatics (e.g., mineral spirits): very good to excellent

Overprint bleed/solvent bleed: moderate; depends strongly on solvent ratios, film build, resin polarity, and substrate.

Lightfastness in inks: mid‑range typical of monoazo lakes; confirm per your end‑use exposure.

Heat stability in inks: commonly acceptable for solvent gravure drying profiles; confirm for your oven conditions and lamination cure.

Anchor your resistance checks to recognized standards and application workflows:

Use the solvent/liquid resistance framework in ISO 2836:2021 — assessment of resistance to solvents and liquids to define and document ethanol, ethyl acetate, and aromatic rub tests and overprint bleed assessments.

Prepare gravure lab prints per ISO 2834‑2:2022 — laboratory preparation of solvent-based gravure test prints so your resistance results are comparable across trials and suppliers.

System-by-system guidance

NC/toluene gravure inks (surface print)

NC/toluene systems often deliver excellent wetting and fast release, which helps PR48:2 reach gloss and density quickly. Two points deserve attention:

Solvent power and bleed: high aromatic content can increase the risk of overprint bleed, especially over white or on low‑surface‑energy films. Control by optimizing solvent balance (aromatics/alcohol/ester), reducing local film build in overprints, and verifying with ISO 2836 rub/bleed on production substrates.

Storage stability: toluene‑rich systems may mask early flocculation; monitor viscosity drift and gloss/strength retention over time, and use NC‑compatible dispersants to stabilize the final PSD.

Action items: design a rubric for acceptable bleed (e.g., no visible stain after X double rubs with ethanol or EA swab, and no halo after Y minutes of wet overprint contact), then test on target BOPP/PET at production coatweights.

Alcohol/ethyl acetate NC gravure inks — PR48:2 for gravure inks in balanced alcohol/EA systems

Alcohol/EA blends are widely used for flexible packaging. PR48:2 typically disperses readily and maintains gloss if the PSD tail is controlled.

Ester‑rich risks: ester‑driven swelling of some resin domains can soften the film early in drying, increasing transient bleed. Manage with flash zones and solvent balance (slightly higher alcohol content for faster surface set), and check overprint intervals.

Viscosity control: monitor for slow drift during storage, which can hint at flocculation; ensure your dispersant selection matches the NC and plasticizer package, not just the pigment surface.

Action items: define NPIRI grind acceptance at ink stage, verify density/gloss vs. coarse tail on the grind gauge, and correlate to on‑press mottle or cell plugging risk.

PU/PA lamination‑compatible inks

You can use PR48:2 in inks intended for downstream lamination with PU/PA adhesives, but migration/bleed controls must be explicit. The workflow matters more than any single pigment property.

Build your test plan around the packaging route: surface print on PET/OPP, adhesive lamination to PE, cure, then migration screening with appropriate food simulants and time/temperature per regulation.

Follow the screening/verification logic in the industry guidance: see the EuPIA Guidance on Migration Test Methods (2023 update). For regulatory conditions and simulants, consult Regulation (EU) No 10/2011 on plastic materials and the plastics migration test methods in EN 1186. A complementary adhesive perspective appears in BfR Recommendation XXVIII on polyurethane adhesives (2024).

Practical note: if low migration is a hard requirement and your screenings show elevated set‑off or adhesive‑side staining, evaluate alternate reds or different PR48 salts via head‑to‑head laminated stack testing before scale‑up.

Dispersion and milling best practices for gravure

Think of dispersion like cooking sugar syrup: you want it smooth, clear, and controlled—no burnt edges and no gritty crystals. For PR48:2, the goals are a narrow particle size distribution (low coarse tail), stable deflocculation, and low‑viscosity flow that releases cleanly from gravure cells.

Fineness target and QC: use the NPIRI grind gauge as your common language. Establish acceptance using ASTM D1316 — Fineness of Grind by the NPIRI Grindometer. Document the largest particle size observed and correlate to gloss and density.

Bead milling: select bead size to control energy input without excessive heat (small to medium beads commonly favored for organic reds). Control temperature to prevent flocculation and resin softening.

Wetting/dispersing aids: choose NC‑compatible anionic/nonionic systems that adsorb to PR48:2 surfaces and remain effective in your solvent polarity; avoid over‑addition that can lower film integrity.

Anti‑settling and storage: consider rheology modifiers compatible with NC to mitigate hard‑settling without hurting transfer. Record viscosity at defined temperatures over time as part of QC.

Test methods and acceptance criteria you can adopt

Standardized methods align teams and suppliers, and they help you troubleshoot faster when something shifts on press.

Solvent/liquid resistance and bleed: Define rub and overprint bleed criteria using ISO 2836:2021. Specify test liquids (ethanol, ethyl acetate, toluene/xylene proxies where appropriate), rub pressure/cycles, contact time for wet overprint, and pass/fail visual ratings.

Gravure lab prints: Prepare test prints per ISO 2834‑2:2022 to control film build, drying, and substrate selection. This removes “apples vs oranges” debates in vendor trials.

Fineness of grind: Use ASTM D1316 and couple the gauge reading to spectrodensitometry and gloss so PSD targets are meaningful.

Lamination/migration workflow: For food‑contact‑adjacent use cases, build screening around the EuPIA Guidance on Migration Test Methods and regulatory conditions from EU 10/2011 with plastic test methods in EN 1186. Keep records tied to each laminate stack and cure schedule.

Comparative view: PR48 family and a common alternative

Below is a qualitative comparison to help frame screening priorities. Values are generalized and must be confirmed with your chosen grade and tests.

Pigment (salt/chemistry) | Shade note in inks | Solvent resistance (alcohol/EA/aromatics) | Overprint bleed tendency | Lightfastness in inks | Heat handling in inks | Typical use note |

|---|---|---|---|---|---|---|

PR48:1 (barium) | Rubine, slightly yellower | Very good / Excellent / Very good | Moderate | Mid‑range | Suitable for normal drying | Broadly used in solvent/offset |

PR48:2 (calcium) | Bluish rubine, semi‑transparent | Very good / Excellent / Very good | Moderate (manage by test/formulation) | Mid‑range | Suitable for normal drying | Workhorse for NC gravure |

PR48:3 (strontium) | Rubine, often slightly yellower than 48:2 | Very good / Excellent / Very good | Often lower bleed risk in some systems | Mid‑range | Suitable for normal drying | Consider when bleed risk is critical |

PR53:1 (naphthol) | Redder, less bluish | Very good / Very good / Good | Variable by grade | Mid to higher in some systems | Acceptable with care | Alternate for specific shades |

Practical examples and stepwise workflows

A. NC/toluene gravure red (surface print) — example workflow

Objective: high‑gloss rubine process red for BOPP with controlled overprint bleed over white.

Pigment selection: PR48:2 with NC‑compatible surface treatment.

Vehicle: NC (RS grades), plasticizer as required, solvent blend leaning to toluene with supporting ethyl acetate/ethanol for balance.

Dispersant: NC‑friendly wetting/dispersing aid dosed to pigment surface area.

Milling: high‑speed disperser pre‑mix, then bead mill with temperature control; target narrow PSD with low coarse tail per your NPIRI acceptance.

Letdown: adjust solids for gravure viscosity and cell release; add anti‑settling if storage requires it.

QC checkpoints: NPIRI grind at production temperature, density and gloss on PET/BOPP lab prints per ISO 2834‑2, overprint bleed per ISO 2836 with ethanol and ethyl acetate rubs, visual halo check after wet‑on‑wet contact.

Neutral supplier example: PR48:2 from Honor Pigments can be incorporated following the process above; validate PSD, gloss, and bleed to your internal acceptance criteria before press trials.

B. PU/PA lamination‑compatible ink — screening and verification workflow

Objective: surface‑printed PET subsequently laminated to PE using a PU/PA adhesive; limit set‑off and potential migration.

Formulation base: PR48:2 in an alcohol/EA‑balanced NC system tuned for fast surface set and controlled film weight.

Cure and laminate: print on PET, dry, apply PU/PA adhesive per spec, laminate to PE, and cure under production‑representative time/temperature.

Screening: conduct set‑off checks under pressure, then migration screening with food simulants and time/temperature conditions aligned with Regulation (EU) No 10/2011 on plastics and the plastic test methods in EN 1186, following the structure proposed in the EuPIA Guidance on Migration Test Methods (2023).

Decision gate: if screenings are marginal, consider reducing film build, extending cure, or testing alternate reds (including other PR48 salts) under identical laminate conditions.

Troubleshooting and QC checklist

Overprint bleed observed on press

Likely causes: excessive aromatic fraction; insufficient flash/dry; high local film build; flocculation increasing free dye sites.

Correctives: rebalance solvent (increase alcohol/EA for surface set), adjust anilox/cell volume, improve flash/oven zoning, optimize dispersant level and milling temperature.

Loss of gloss or density vs. lab

Likely causes: coarse PSD tail; press temperature rise causing flocculation; substrate energy mismatch.

Correctives: tighten NPIRI acceptance, increase cooling in milling, confirm corona treatment and cleanliness of film.

Viscosity drift in storage

Likely causes: slow flocculation; incompatible dispersant; solvent loss.

Correctives: adjust dispersant chemistry/dose, incorporate NC‑compatible anti‑settling, improve container closure and headspace control.

Lamination set‑off or staining

Likely causes: insufficient dry/cure; adhesive interaction; excessive film build.

Correctives: extend drying or cure, tune adhesive mix/cure profile, lower coatweight, verify with laminate stack tests.

When to consider alternatives or different PR48 salts

Switch when your tests (not assumptions) indicate an unacceptable risk envelope. Triggers include:

Persistent overprint bleed in aromatic‑leaning systems despite solvent balance and PSD control.

Low‑migration laminate targets that fail screening/verification despite process optimization.

Shade targets requiring a different hue location or higher outdoor fastness than typical monoazo lakes provide.

In these cases, design a controlled comparison: hold vehicle, solvent balance, PSD target, film build, substrate, adhesive, and cure constant; swap only the red pigment family or salt. Evaluate against the same ISO 2836/2834‑2 and laminate migration workflow. The result is data you can defend in a customer audit.

Closing: actionable next steps

Lock your lab methods: ISO 2836 for resistance/bleed, ISO 2834‑2 for gravure lab prints, ASTM D1316 for grind control.

Codify acceptance criteria that tie NPIRI readings to gloss and density on your target films.

For lamination, implement the EuPIA‑aligned screening/verification workflow before scale‑up.

Keep a slim alternate‑red matrix ready for quick A/B testing when bleed or migration tightens.

For a concise view of pigment categories commonly used in printing inks, explore the neutral, high‑level overview at Pigments for Printing Inks — Honor Pigments. Validate all selections with internal tests before commercial production.