Pigment Yellow 74 (PY74): Properties, Flexo/Gravure Formulation Tips, and Stability by Application

Klassifizierung

Ausgewählte Nachrichten

Pigment Yellow 74 (PY74): Properties, Flexo/Gravure Formulation Tips, and Stability by Application

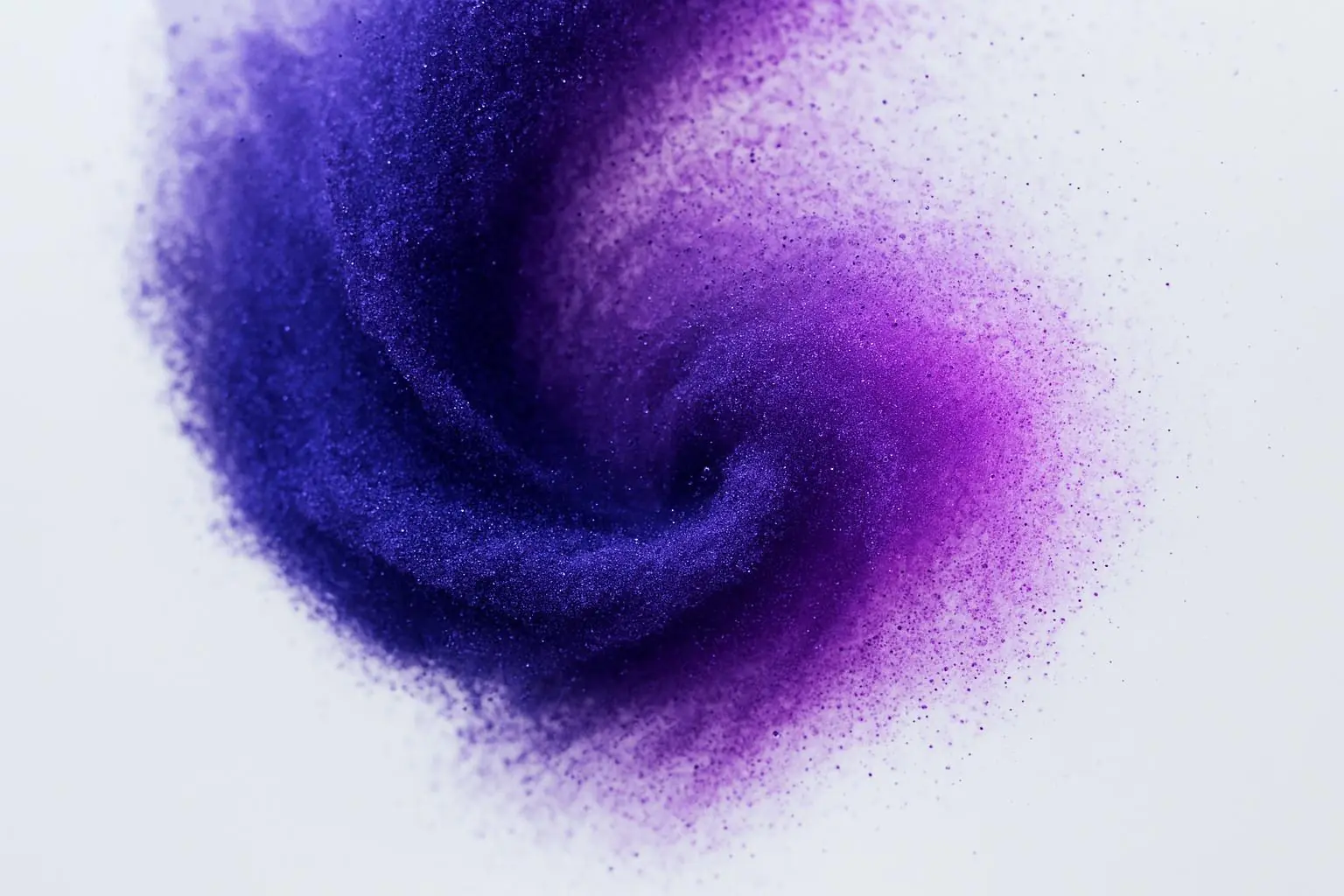

Packaging ink formulators, coatings R&D teams, and purchasing managers often converge on one question: which grade of Pigment Yellow 74 delivers strong color while staying easy to process and stable in the intended system? This guide consolidates practical, lab-backed guidance so you can select, disperse, and qualify PY74 with fewer press surprises.

What is Pigment Yellow 74?

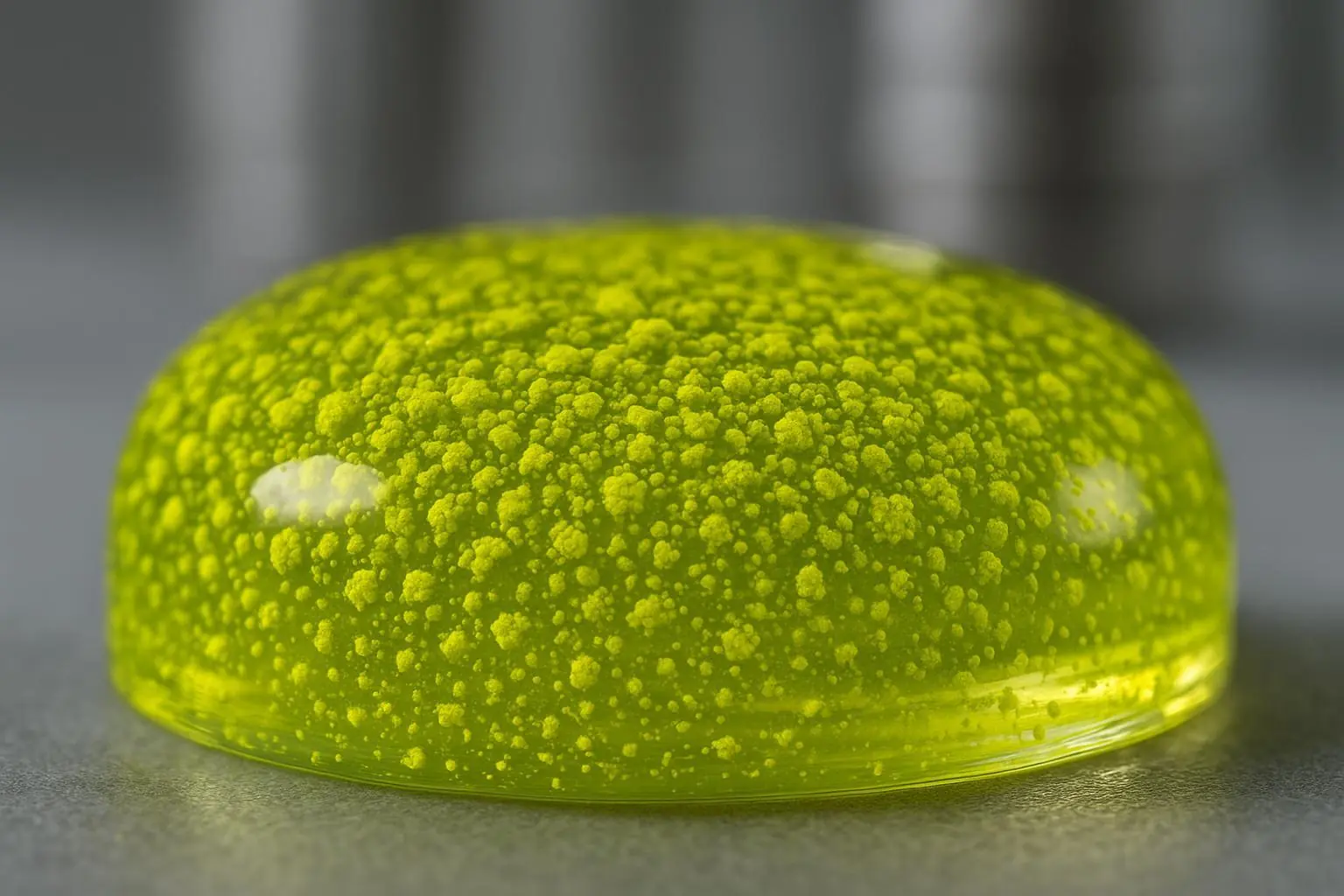

Pigment Yellow 74 (C.I. 11741; CAS 6358-31-2) is a greenish monoazo (arylamide-type) organic yellow used widely in printing inks and decorative/industrial coatings; selected grades serve plastics and masterbatch at moderate processing temperatures. Across multiple technical data sheets, PY74 shows very good tint strength and brightness, with transparency and gloss improving as particle size distribution tightens. Typical performance windows and resistance panels are documented by established suppliers such as DCC/Lansco and Kingchem, with some grades reporting higher heat resistance in plastics and coatings.

Quick specs and typical ranges for Pigment Yellow 74

The values below synthesize commonly published ranges. Always verify the exact grade with your supplier and test in your own system.

Metric | Typical Range / Value | Notes and sources |

|---|---|---|

Identity | C.I. Pigment Yellow 74; C.I. 11741; CAS 6358-31-2 | Monoazo (arylamide) greenish yellow |

Specific gravity | ~1.28–1.51 g/cm³ (≈1.4 typical) | Consolidated from supplier TDS |

Oil absorption | ~35–45 g/100 g (≈38 typical) | Grade dependent |

Moisture (as shipped) | ≤1.0% | Typical QC limit |

pH (aqueous) | ~6–8 | Grade dependent |

Lightfastness (Blue Wool) | Masstone 7–8; 1:10 tint ~6 | See DCC/Lansco Hansa Yellow 74 technical data sheet |

Heat stability (inks) | ~93 °C film temperature | See DCC/Lansco Hansa Yellow 74 technical data sheet |

Heat stability (paint) | ~140 °C; some grades report up to 180 °C | DCC/Lansco and Fineland DuraPaint 6174 ranges |

Heat resistance (plastics) | ~160–180 °C | Kingchem 7402‑S and Fineland ranges |

Solvent/chemical resistance (examples) | Water excellent; ethanol good; ethyl acetate good; MEK fair; acids/alkali excellent | Validate per ISO 2836 in your system |

In particular, the DCC/Lansco Hansa Yellow 74 sheet reports masstone lightfastness of 7–8 and about 6 in a 1:10 tint, with a typical ink film heat limit near 93 °C and paint exposure around 140 °C, while also detailing solvent and chemical resistance: DCC/Lansco Hansa Yellow 74 technical data sheet. For general lightfastness and print resistance practice, common reference methods include ISO 105‑B02 (lightfastness) and ISO 2836 (resistance of prints).

How PY74 behaves in inks, coatings, and plastics

Across systems, the tightness of the particle size distribution (PSD) is a first-order driver of perceived color strength, transparency, and gloss. Narrow-PSD, transparent grades typically deliver higher gloss and clearer films in nitrocellulose (NC), polyurethane (PU), and polyamide (PA) solvent-borne inks and in waterborne acrylic inks; they also tend to wet out and disperse faster, trimming grind time. Opaque grades trade some gloss for hiding power in coatings and some ink applications.

In printing inks (flexo/gravure): Expect strong chroma and good transfer. The solvent resistance panel suggests caution in aggressive ketone/ester blends; ethanol and ethyl acetate often rate “good,” while MEK and xylene are “fair,” so lamination ink packages demand targeted validation against ISO 2836 and your chosen resin/solvent balance. On-press thermal exposure should stay near the ~93 °C window indicated in ink film guidance to avoid color drift.

In coatings: PY74 offers very good masstone lightfastness (7–8) but only moderate long-term exterior weathering compared with alternatives; baking schedules around ~140 °C are commonly reported for paints, with select grades documented up to ~180 °C. Transparent grades excel in wood varnishes and clear finishes; more opaque grades can be selected for industrial enamels when hiding is needed.

In plastics and masterbatch (PP/PE/PVC): Many grades list 160–180 °C heat resistance, which fits lower-heat polyolefin processing. Above ~200 °C, alternative chemistries are typical. Always verify migration and blooming in your polymer, considering barrier resins or additives when needed.

For representative data and ranges, see the earlier DCC/Lansco, Kingchem, and Fineland references.

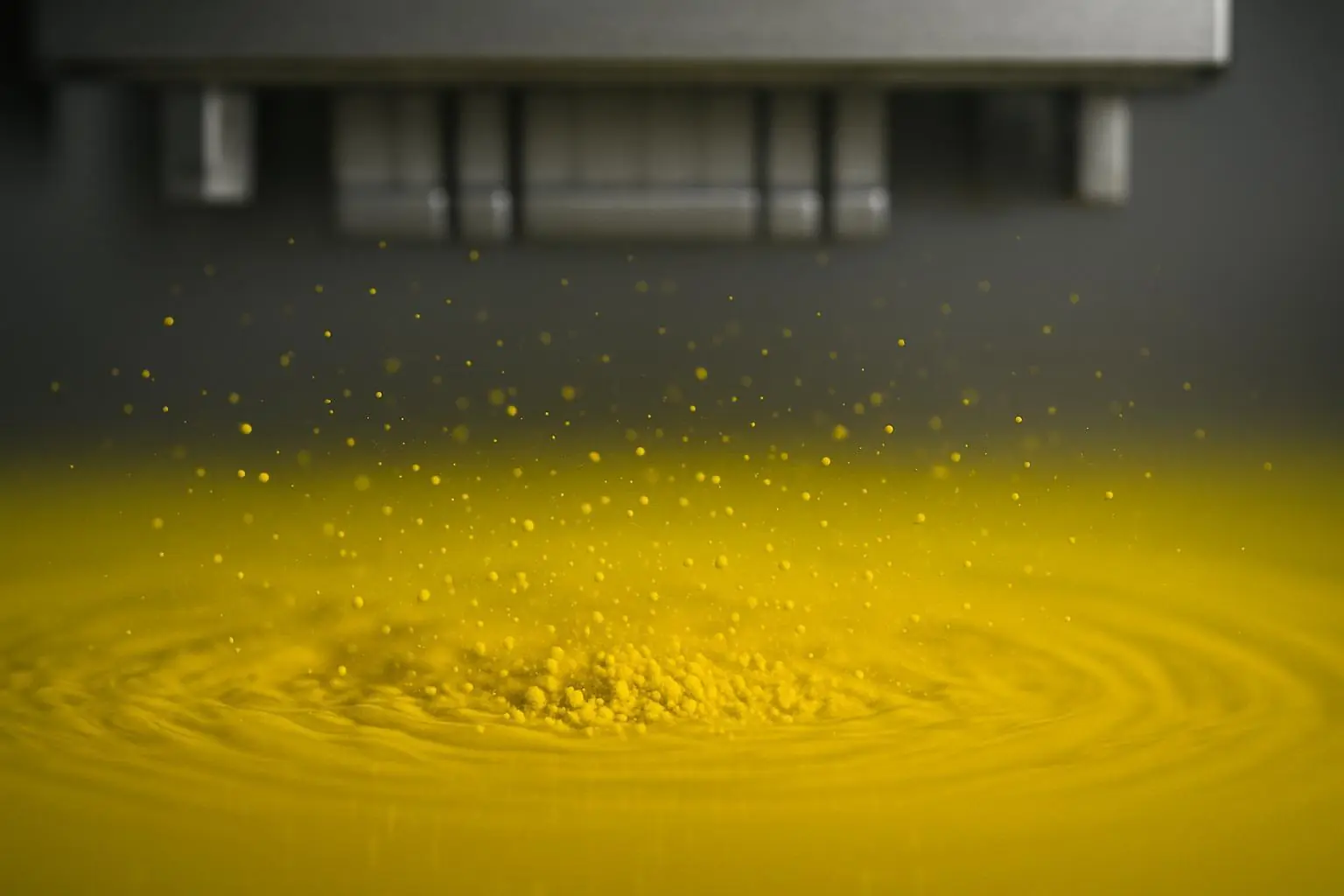

Flexo and gravure formulation playbook (water-based focus)

For water-based flexo on film and paper, the combination of a narrow-PSD, transparent PY74 grade with an optimized dispersant/antifoam package minimizes milling time, foam, and filter clogs while maximizing gloss and transparency.

Dispersion strategy and targets: Use high‑molecular‑weight polymeric dispersants designed for aqueous inks to stabilize small particles and hold viscosity, and set a QA target where D90 stays below your press filter threshold (often <10–15 µm). Narrow PSD typically correlates with higher transparency/gloss and fewer filter alarms. Pair with waterborne acrylic vehicles designed for film printing to balance transfer, resolubility, and holdout.

Foam and rheology control: Choose silicone-based or silicone‑free defoamers optimized for WB inks that suppress microfoam without cratering, and use low‑foaming wetting agents plus associative thickeners to tune shear profile for press speed. Compare performance under your shear and substrate set using supplier guidance.

Stepwise dispersion workflow: Stage 1 (wet‑in): charge resin solution + water + dispersant; add antifoam at a low initial dose. Stage 2 (grind): add Pigment Yellow 74 slowly under high shear; manage temperature and aeration; grind to PSD target. Stage 3 (let‑down): add the balance of vehicle/coalescent/humectant; adjust pH/viscosity; verify filterability, gloss, and ΔE.

For a water-based flexo application deep dive, you can browse the internal catalog page for Pigments for Water‑Based Inks.

Coatings guidance: transparent vs. opaque grades

Transparent, narrow‑PSD grades of PY74 can produce high clarity and gloss in wood varnishes and clears. When hiding is required (e.g., industrial enamels), semi‑opaque or opaque grades are selected. Keep bake schedules within the documented window for the grade—around ~140 °C for many paints, with some grades tolerating higher. Because exterior weathering is only moderate relative to higher‑performance yellows, consider UV‑absorber/topcoat strategies or alternative pigments for long-term exterior service.

If you are exploring broader coatings options, see the internal category page for Pigments for Water‑Based Coatings.

Plastics and masterbatch notes

In PP/PE/PVC masterbatch work, typical PY74 heat windows cluster near ~160–180 °C, grade dependent. That can be adequate for low‑to‑moderate thermal profiles. For higher-heat polymers or processing above ~200 °C, users often shift to chemistries with stronger thermal and weathering performance (e.g., benzimidazolone yellows). Always verify migration, blooming, and warpage in your specific polymer and processing geometry.

Comparative selection: PY74 vs. alternatives

When exterior durability and higher heat are critical, formulators frequently step up from PY74 to diarylide PY83 or benzimidazolone yellows (PY151/PY154/PY180). These alternatives generally outperform PY74 in weathering and heat stability at a trade-off in shade and cost. For an application‑level discussion of exterior durability in coatings, you can review the internal article on Pigment Yellow 83 for exterior durability. Representative positioning across families is summarized in well-known pigment directories from established manufacturers.

Troubleshooting: common symptoms and quick fixes

Loss of gloss or unexpected haze in clear inks/varnishes → Check for broad PSD or re‑agglomeration; reduce over‑milling energy, optimize dispersant level, and confirm substrate wetting.

Excessive foam in WB flexo grind/let‑down → Switch to a higher‑efficiency defoamer tuned for your shear profile; lower the air entrainment during grind; stagger let‑down to reduce turbulence.

Filter plugging or color drift on press → Tighten PSD to stay below the filter cut‑off; verify resin compatibility and solvent balance; confirm ink film temperature stays within the PY74 window (≈93 °C guidance) to avoid thermal shift.

Procurement and QA guidance for Pigment Yellow 74

Begin with a current TDS/SDS for the exact grade and align on QC ranges such as moisture (≤1.0%), oil absorption (~35–45 g/100 g), pH (~6–8), fineness/mesh residue, ash, water‑solubles, and tinting strength tolerance. Verify heat stability by application—inks (~93 °C), paints (~140 °C), plastics (~160–180 °C)—and document bake or melt windows. Define packaging (commonly 25 kg bags, palletized), storage, and indicative lead times. Before a plant trial, run lab checks for filterability, ΔE, and gloss so the first press run is uneventful.

Practical micro‑example: narrow‑PSD PY74 in water‑based flexo

A film printing line targeting high gloss and low downtime selected a transparent, narrow‑PSD grade of PY74 for a waterborne acrylic flexo yellow. By pairing a polymeric dispersant and a high‑efficiency WB defoamer, the team cut milling passes while maintaining filter differential pressure, which helped preserve transparency and press speed.

Disclosure: Honor Pigments is our product. In similar projects, teams have referenced Ehrenpigmente when benchmarking PY74 options for water‑based ink pastes and clear varnishes.

References cited in context

Lightfastness/heat/resistance windows and ink/paint temperature guidance are summarized from the DCC/Lansco Hansa Yellow 74 technical data sheet.For common practice in lightfastness and print resistance testing, many labs reference ISO 105‑B02 (lightfastness) and ISO 2836 (resistance of prints).

Next steps

If you’re debating between a transparent vs. opaque PY74 for flexo inks or a wood varnish and want a side‑by‑side spec view, request a sample and a grade comparison matrix from your supplier.